3D Print Provisionals and Wax-ups

Fabricate provisionals and wax-ups for restorative and cosmetic procedures with SprintRay 3D printers.Providing temporary restorations and provisionals for aesthetic work provide your patient with a great temporary solution between treatment approval and final placement. Offering next-day waxup presentations can dramatically increase case acceptance for aesthetic procedures and help set patient expectations.

Because they can print in less than an hour and cost only a few dollars in materials to make, you can 3D print provisonals and temporaries a nominal fee, increasing patient access. Plus, rapidly replace broken or lost restorations from digital records, with no need to re-take impressions.

Key Benefits

Temporary Restorations

3D print provisionals, crowns, and bridges for patients undergoing treatment. At only a few dollars per part to manufacture, flexibility in fees can help improve patient acceptance. And, because they can be produced in less than an hour, practices can now fabricate temporaries on the same day they're needed.

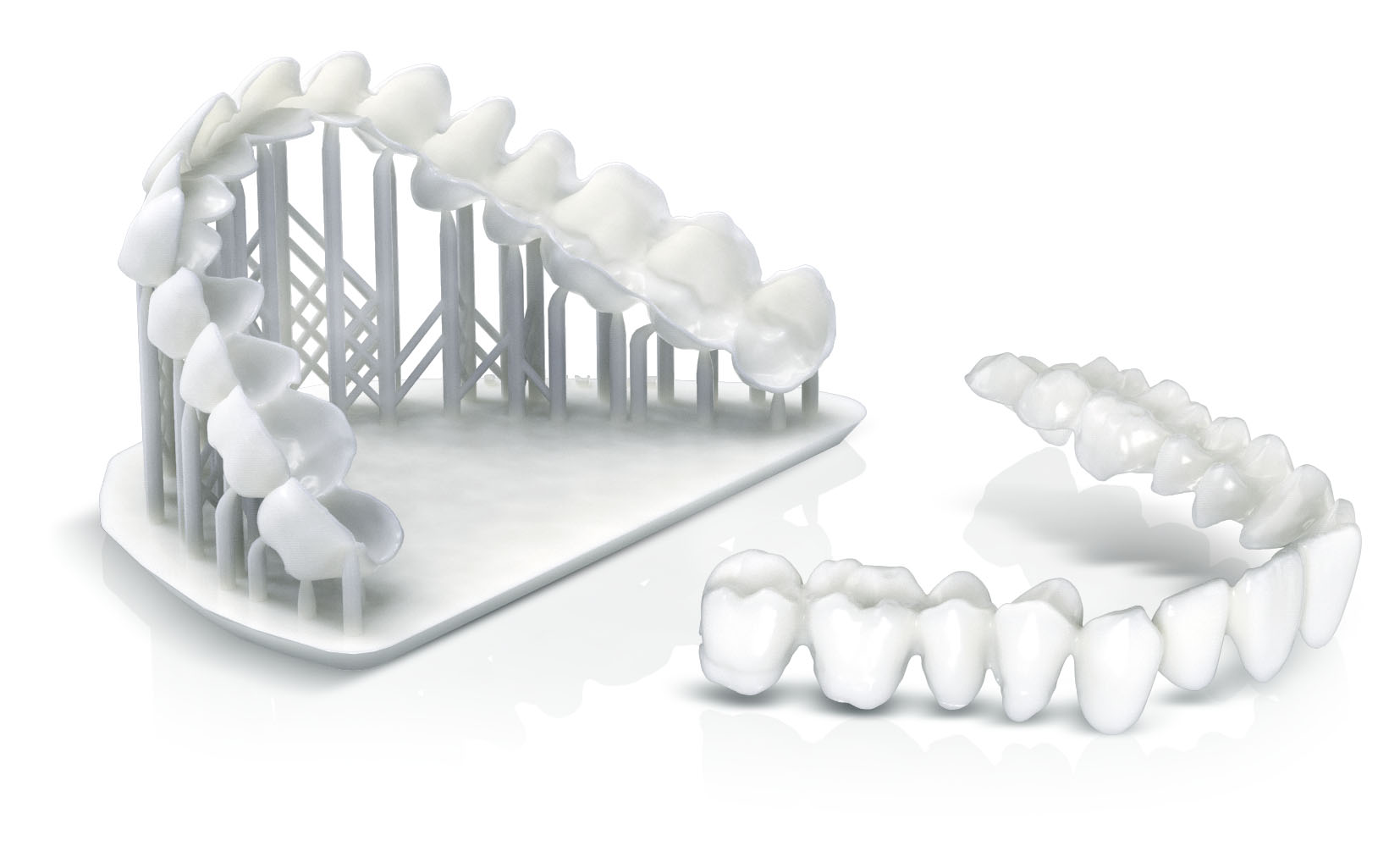

Aesthetic Wax-Ups

Final aesthetic restorations such as veneers are the result of experienced craftsmen. But your patients don't have to wait for the final product to see the results up close and in-person. With 3D printing, you can fabricate physical, beautiful wax-ups for patient presentation in a matter of hours.

Dr. Fung's High-Speed Wax-ups

Dr. Lawrence Fung's Los Angeles practice was built from the ground-up to leverage digital technologies: intraoral scanning, advanced photography, and digital design all figured prominently in his daily workflow. Despite this, Dr. Fung was initially hesitant to adopt a 3D printing. But after only a few months, Dr. Fung has leveraged his printer to drastically increase case acceptance for cosmetic procedures, providing intra-oral wax-ups in just 24 hours for most of his patients.

Connect with Digital Dentistry Experts

The Power of Dr. Zhivago's 3D-Printed Provisionals

Dr Zhivago uses his SprintRay 3D printer to provide rapid wax-ups for his patients' aesthetic and restorative procedures. Thanks to the low unit cost of each set of provisionals, he is able to provide his patients with spares in the case of loss or breakage, which is a huge boon to his world-travelling patient base. Learn how 3D printing is revolutionizing Dr. Zhivago's office in this Practice Insight.

Digital Workflow Explained

3D Printing Provisionals and Wax-upsUsing an intraoral scan and optional CBCT data, you can use 3rd-party software or work with a digital designer to create the digital model for the final restoration. Once you have your design, send one copy to your lab for production and import the other into RayWare to print using the material of your choosing.

Materials

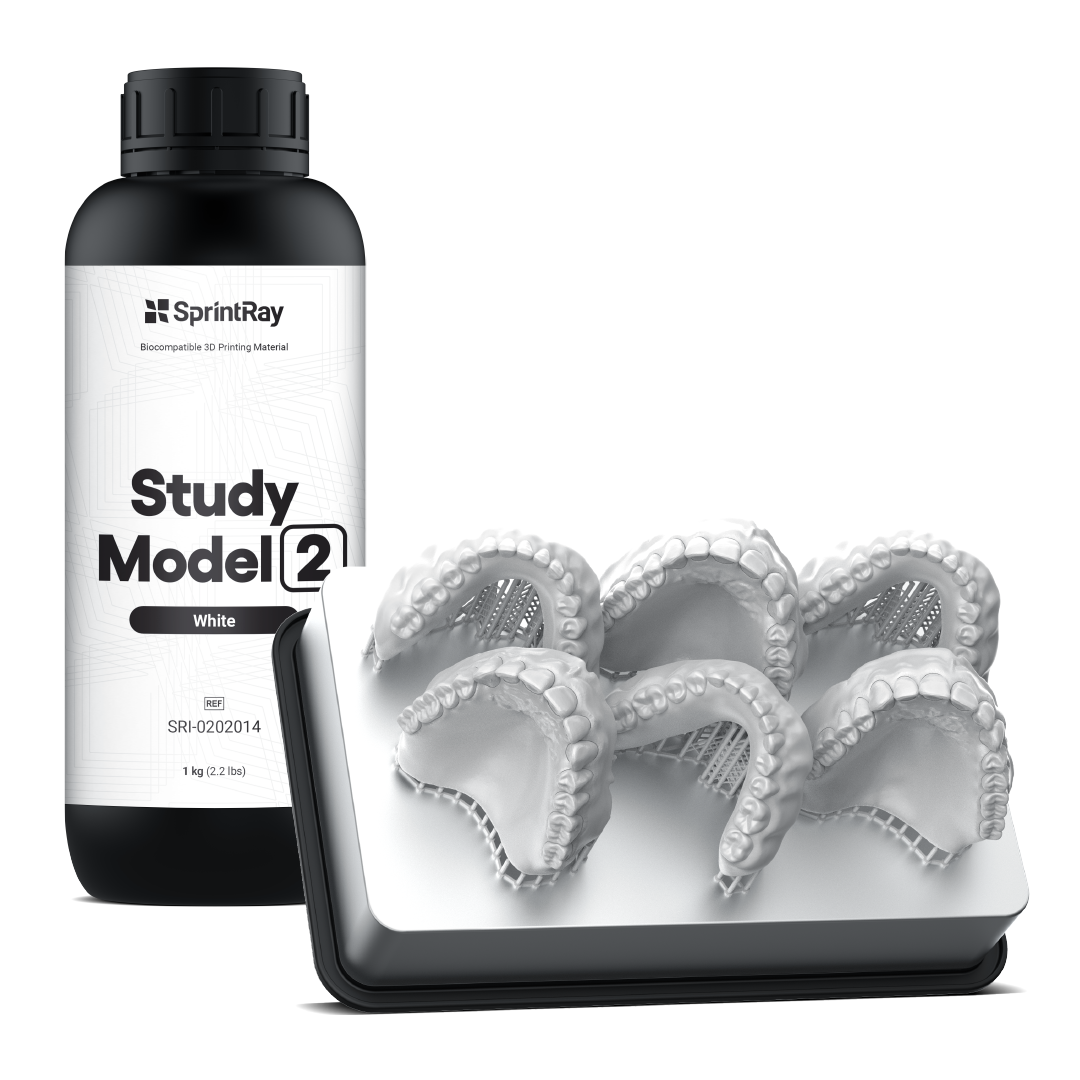

SprintRay Study Model White 2

Rapid, pure-white models for patient presentationSprintRay Study Model White 2 is a special material formulation that provides outstanding color, clarity, and production speed, making it perfect for patient presentation. With a 20% increase in curing efficiency, you can offer same-day mockups and waxups. Plus, get pure white prints every time thanks to an improved color formulation that doesn’t discolor during post-processing.

PRODUCTION TIME

Higher speed means faster model production, allowing for same-day waxup and diagnostic models.

Study Model White 2

Die & Model 2 Gray

More Accurate than Stone

A recent university study found SprintRay Pro more accurate and consistent than traditional alginate methods. With an average RMS of 129±16μm for 3D printing compared to 177±25μm for alginate methods, SprintRay Pro is ready to meet the clinical demands of contemporary dentistry

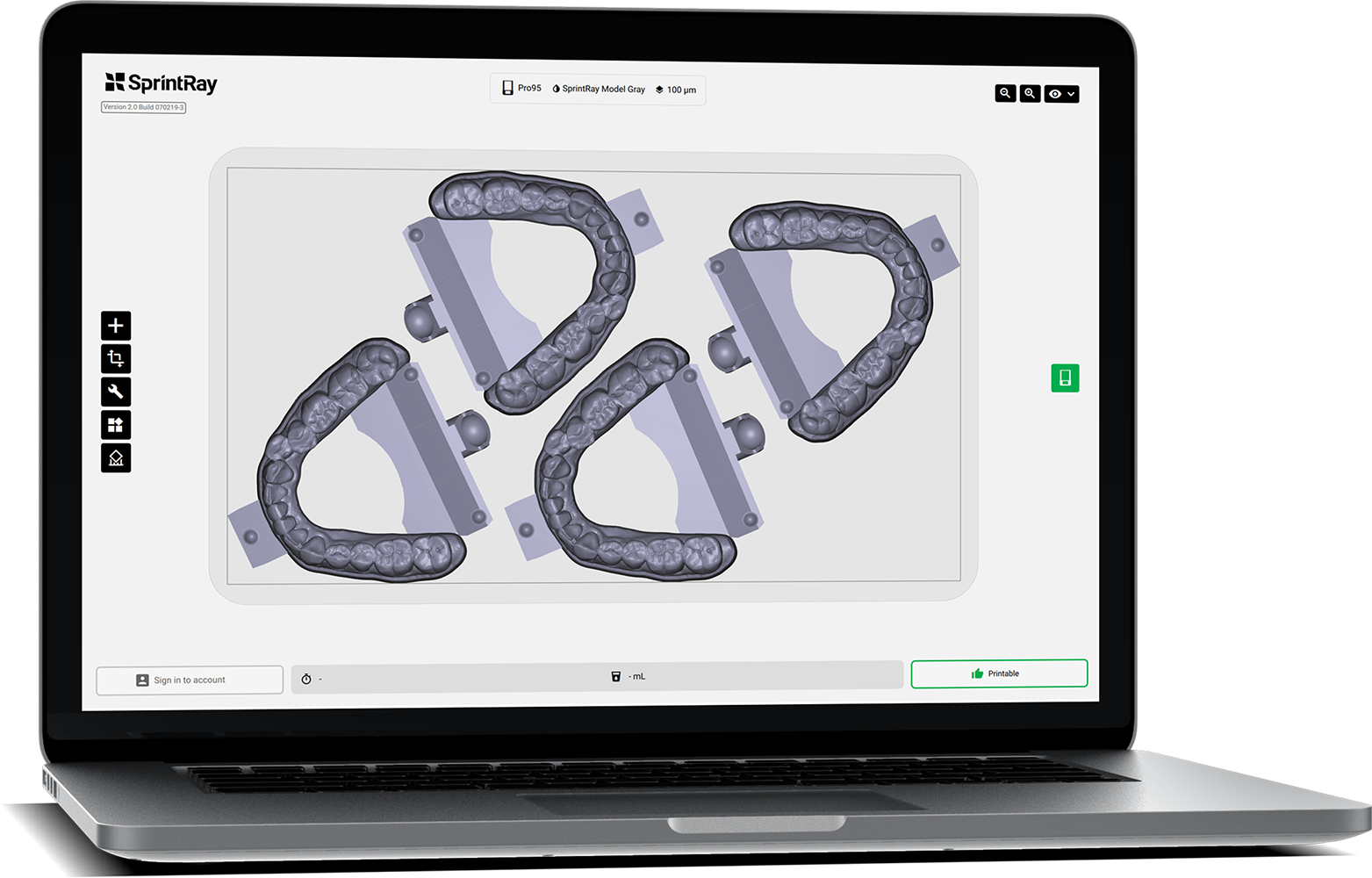

Dental 3D Printing Control Center

Compatible 3D Scanners

You can use any scanner type you’d like with RayWare. We accept any .STL formatted scan data. This list of scanners shows many options that our customers often use, but it is not an exclusive list.

Compatible Design Software

RayWare allows you to choose a dental design software that meets your clinical needs. This list shows our recommended options, but RayWare accepts any design file formatted in .STL, which means you can use whatever you’re most comfortable with.