Introducing Digital Press Stereolithography (DPS)

PATENT PENDING

Midas is the ultimate solution for fabricating chairside restorations. It uses patent-pending Digital Press Stereolithography (DPS) to overcome the challenges of printing highly-filled viscous materials.

Reserve Your Midas

What is Midas?

What can Midas do?

Fast

First-ever digital pressDigital Press Stereolithography (DPS) lets you 3D print highly-filled composite restorations in minutes

Digital Press Explained

Easy

AI design, zero upkeepMidas AI Studio generates AI designs you can customize, then easily print in just a few steps

See AI Design Studio

Revolutionary

Viscosity agnosticMidas is immune to resin viscosity, supercharging the future of Biomaterial Innovation for highly-filled composites

What can Midas do?

Capsule

Digital Press

PATENT PENDING

Meet the New King of Chairside

The most revolutionary 3D printing tech ever to reach dentistryWhat can I do with Midas?

Midas uses Digital Press Stereolithography, a patent-pending printing method that replaces the resin, tank, and build platform with a Resin Capsule. This advancement allows Midas to print with highly filled resins that are too viscous to use on a conventional 3D printer.

No viscosity limitations

Small footprint, high output

Zero training, no upkeep

AI restoration design

Multi-restoration printing

Affordable chairside workflow

vs

Desktop Additive

Conventional 3D Printer

Conventional printers are versatile but they cannot use highly-filled, highly-viscous restorative resins.

Multi-application workhorse

Low training and upkeep

Material viscosity limitations

Industrial Additive

Ceramic 3D Printer

Ceramic 3D printers are very expensive and require a huge amount of space. Their workflows are very cumbersome.

Prohibitively expensive

Huge footprint, low output

Cumbersome workflow

Subtractive

Chairside Milling Machine

Chairside mills produce great restorations, but they are prohibitively expensive to buy and maintain.

Single restoration fabrication

Expensive to buy, costly to maintain

Large footprint, low output

PATENT PENDING

One Capsule, Infinite Possibilities

The game changer has arrivedThe Midas Resin Capsule distills the build platform, tank, and material into a single-use item. This innovation unlocks viscosity-agnostic 3D printing while offering incredible speed, accuracy, and workflow simplicity.

Crowns

Full contour crowns with lifelike aesthetics and mechanicals thanks to extremely high filler content

Posterior crowns

Anterior crowns

Implant crowns

Inlay & Onlay

Complex shapes print with pixel-perfect accuracy on Midas - fabricate up to 2 inlays per capsule

Fillings

Onlays

Inlays

Veneers

Print up to 3 incredibly thin, strong veneers per capsule for minimally invasive cosmetics

No-prep veneers

Prepped veneers

Scan. Place. Press.

The easiest way to fabricate chairside restorationsAnyone can print a restoration on Midas. Because it uses resin capsules rather than cumbersome bottles and tanks, printing is as simple as making your morning cup of coffee.

Step 1

Scan

Every Midas Capsule is coded with its material type, shade, manufacturing information, and expiration date. When it’s time to print, simply scan the capsule using the barcode Scanner.

Automatic medical device tracking

Resin and shade detection

Robust error proofing

Step 2

Place

Midas has three printing slots on the heated print glass. After scanning, the onboard computer will tell you where to place the cartridge.

Print up to 3 capsules at once

Capsule placement detection

Fully guided workflow

Applications

Step 3

Press

Midas will start pressing once you’ve scanned and placed all the capsules for a print job. The print loop will slowly lower while the resin is cured.

Print in less than 9 minutes

Mess-free workflow

DPS Explained

Step 4

Remove Print

Remove the capsule from the print glass. Pull the tab on the build platform to remove it from the capsule. Your restoration is ready for post processing.

Hop, Step, and a Quantum Leap

Now, you can place ceramic composite restorations quickly and at a fraction of the cost. Welcome to the future. Welcome to Midas.

DPS Explained

Easy Design Workflow

AI-assisted Midas Design Studio generates restorations in momentsAI Studio combines the convenience of AI design with the versatility of CAD to create a simple, cloud-based design suite. Designing a restoration with Studio is easy for anyone, while customization options like margin and adaptation adjustments help create a perfect fit.

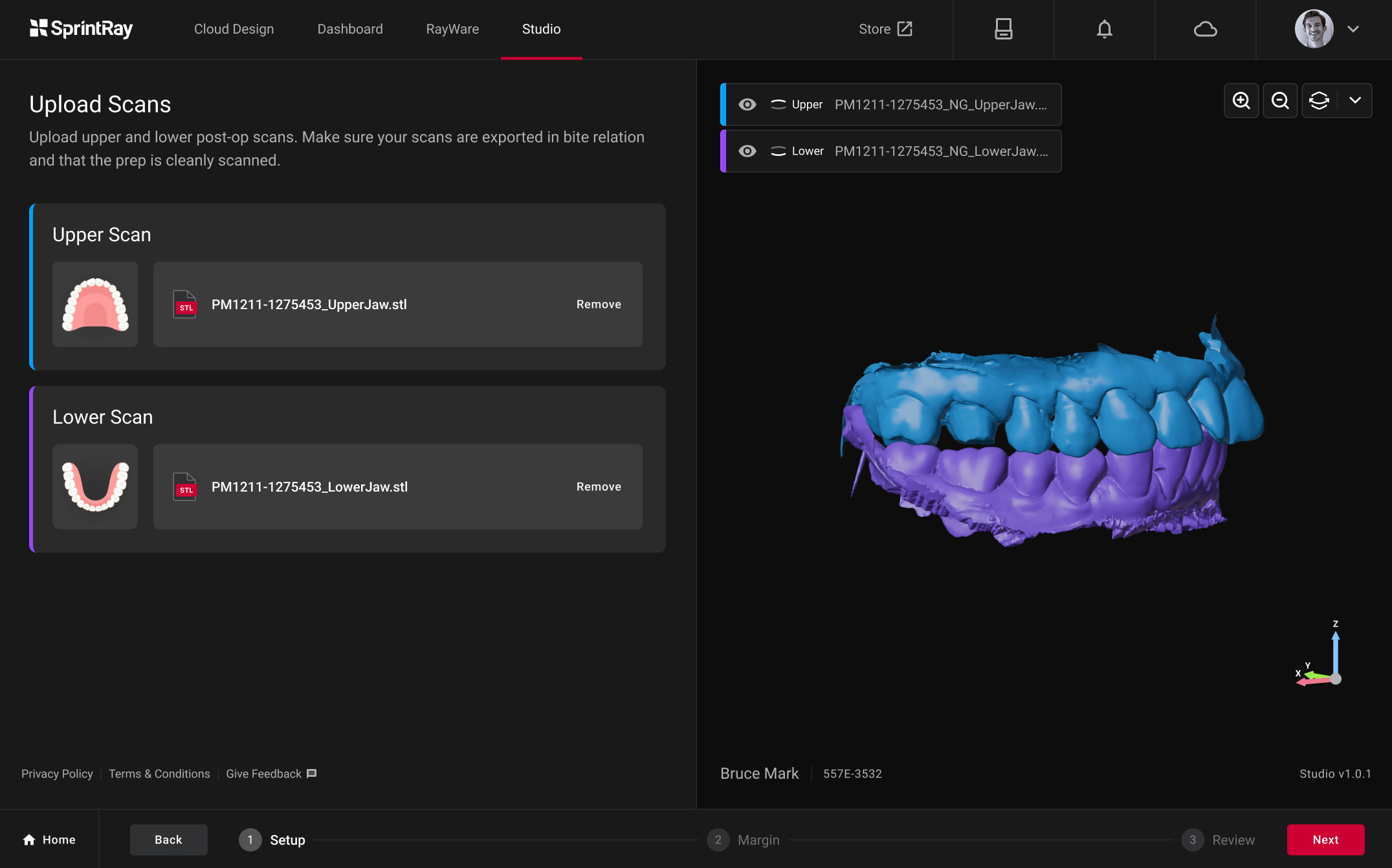

Step 1

Upload Scans

AI Studio takes upper and lower post-op scans

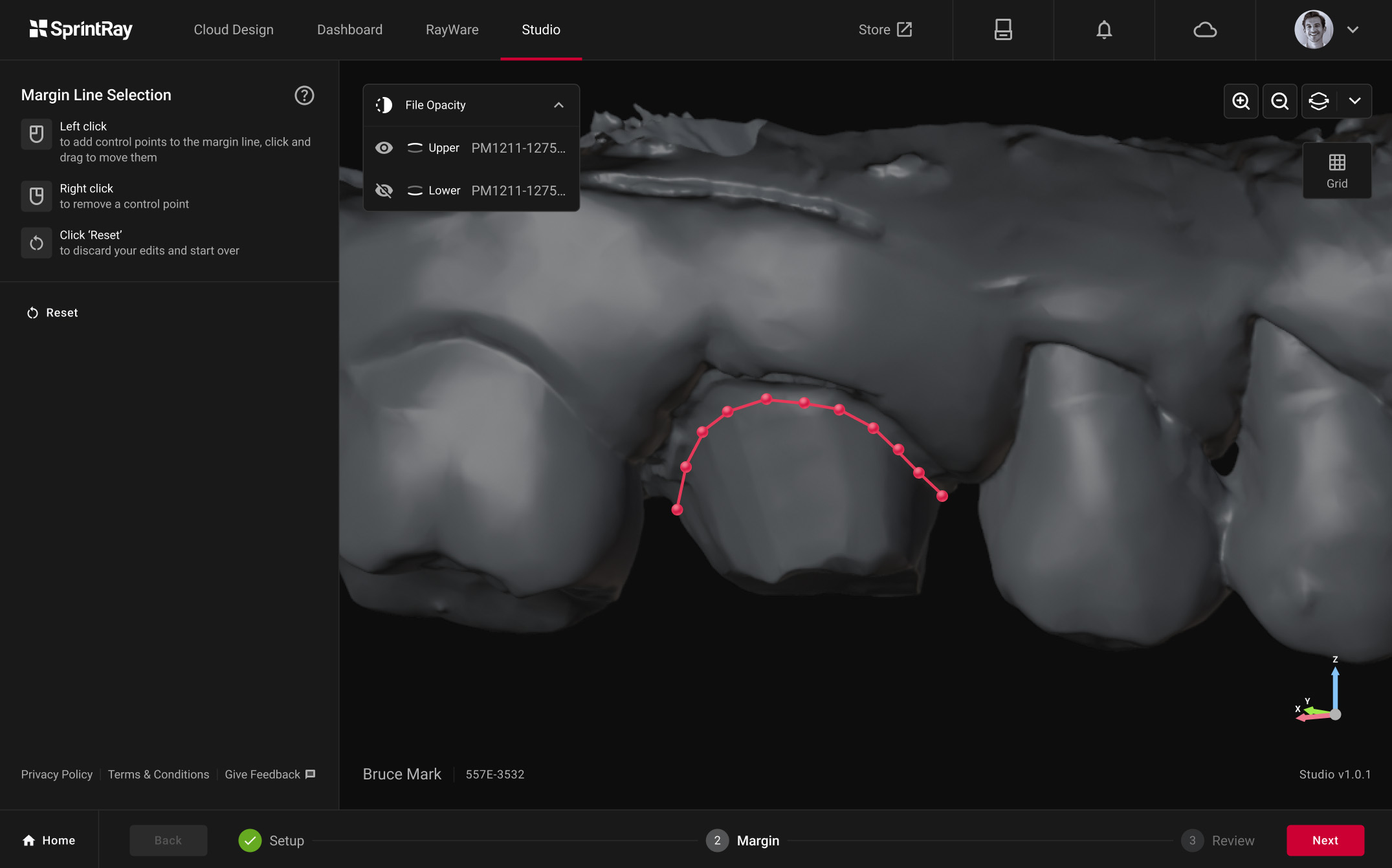

Step 2

Confirm Margin

Adjust the automatic margin line to get the perfect crown

Automatic margin detection

Margin editing

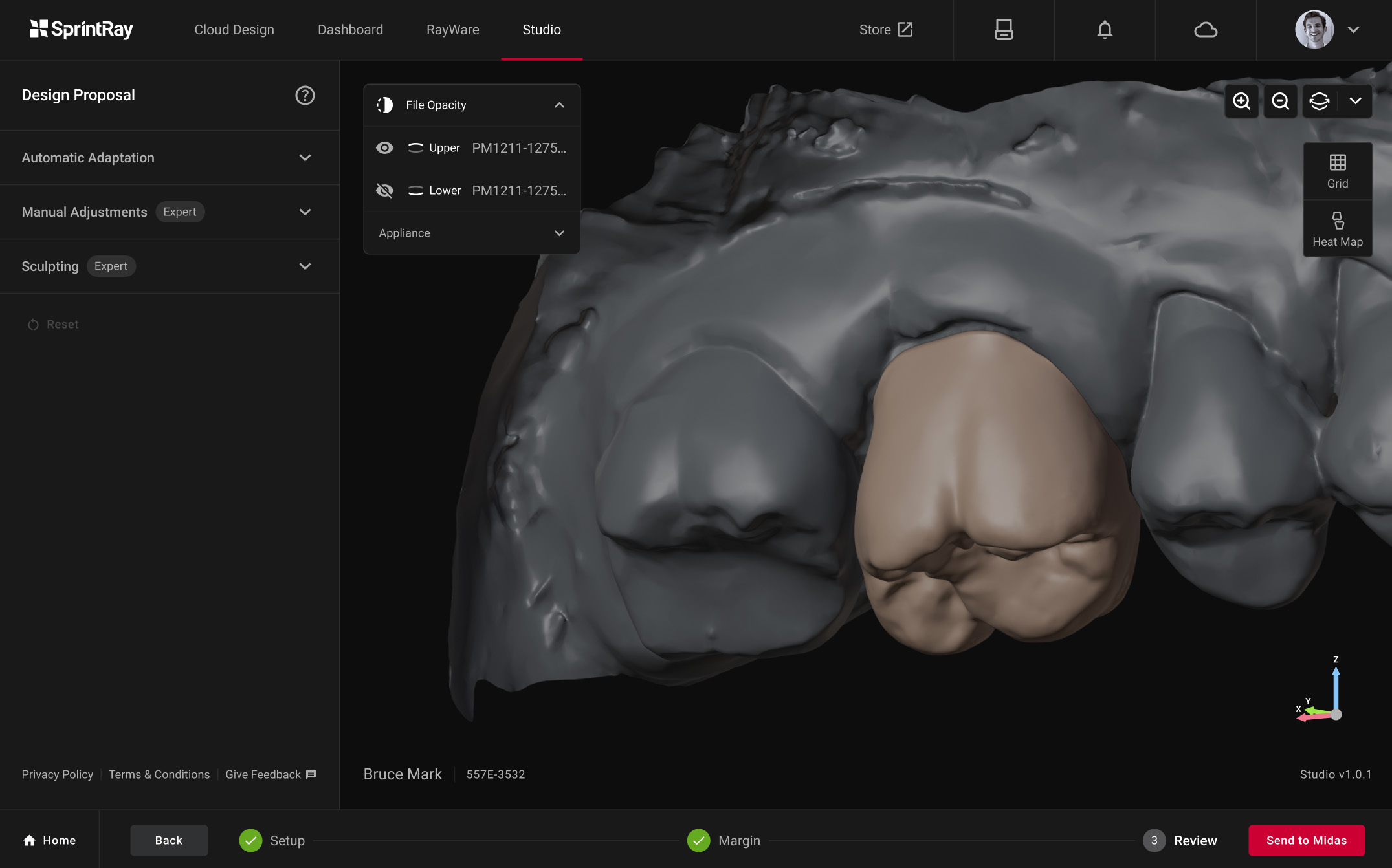

Step 3

Final Touches

Adjust the aesthetics and final positioning

Automatic adaptation

Manual positioning

Anatomical sculpting

Step 4

Print on Midas

Send your crown design directly to Midas to print in under 10 minutes - now that's chairside service

See Workflow

Every Considered Detail

Engineered for precision, designed for your workflowTo build a product as revolutionary as Midas, we left no stone unturned. From its thoughtful size and proportions to the materials used in manufacturing, we pulled out every stop to bring Digital Press Stereolithography to your office.

Unparalleled Accuracy

Midas delivers harmony between hardware, software, and workflow. Using a capsule to deliver resin doses eliminates variability from the workflow. Combined with direct projection and 385 nm light, Midas provides outstanding precision.

385 nm Light

Midas uses 385 nm UV-A light for incredible depth of cure control, improving print quality today and resin development tomorrow. This innovation leads to better surface finish, improved layer accuracy, and enhanced fit and finish for pixel-perfect restorations.

Incredibly Compact

Midas is extremely compact because it doesn't need to hold a large tank of liquid resin or a permanent build platform. Midas can be placed almost anywhere it fits - because the resin is stored in sealed capsules, it's less sensitive than a conventional 3D printer.

45 µm Direct Projection

Midas uses a 45 µm projector to directly deliver light to the print glass with minimal distortion and superior precision. Mounting the projector this way simplifies the optical path and removes the need for light reflection, drastically improving accuracy.

PATENT PENDING

Workflow Nirvana

Simplicity unlike any other 3D printerResin capsule technology supercharges the best workflow in dentistry. There is no more exposed resin, resin tanks, or build platforms. Midas makes it simple.

How it Works

Zero Maintenance

Ready for your maintenance checkup? Wipe down the print glass. Seriously - that’s it. No resin tanks, no build platforms, just place and print.

Training-free Workflow

Scan, place, print. The workflow for Midas is really that simple: scan each cartridge and instructing you where to place it. It’s error-free and requires no training.

Medical Device Tracking

The onboard QR code scanner helps simplify the workflow, but it also provides medical device tracking for expiration dates, lot numbers, and more.

Simplified Resin Handling

Midas Capsules come in sets of three so you can easily stock multiple shades and resin types. The included storage container protects them from the elements. It's also stackable, for simplified inventory management.

PATENT PENDING

Digital Press Stereolithography (DPS)

A patent-pending technology by SprintRayDigital press stereolithography (DPS) 3D printing uses hydrodynamic principles to create an environment where the viscosity of the resin is no longer a barrier to speed or accuracy. This technology allows Midas to print up to 3 definitive crowns in 10 minutes, regardless of filler content.

Viscosity Agnostic

A material's physicality does not bind Midas — DPS uses hydrodynamic principles to move material through the stereolithography process.

Space Saver

Midas uses a highly compact design to deliver an incredible size-to-performance ratio. You can fit it almost anywhere due to its small footprint.

Just Getting Started

DPS is the start of a new era of 3D printing. It simplifies the workflow and opens the door to a whole new world of biomaterial innovations.

Before Pressing

Viscous material sits in the pressurized resin chamber. The build platform is tucked into the build cylinder.

while pressing

The material is pressed and dispensed into the build area. Hydrodynamic principles push the build platform up as it cures.

After pressing

When the pressing is finished, the build platform is ready for extraction along with your printed restoration.

Perfect Pair

Midas and NanoCure are better togetherMidas and NanoCure help you deliver definitive restorations with outstanding speed, accuracy, and mechanical properties. These compact, advanced devices can help any office upgrade from outsourcing to chairside care for a fraction of the cost of a mill.

See NanoCure

Supa-fast Workflow

Design, print, and post cure a definitive crown in less than 30 minutes.

Compact Ecosystem

Midas and NanoCure together take up less space than a typical milling machine.

Unlock the Future

With DPS and dual-wavelength curing, your office is ready for the future of biomaterial innovation.

Enter a New Era

Reserve your spot for the future of dentistryMaking a restoration on Midas is like magic. It marks the beginning of a new era where highly-filled composite restorations can be designed and fabricated chairside in minutes. A future where dental care is more economical, responsive, and customizable .

Join the waitlist now to experience a new era of dentistry.

Join the waitlist now to experience a new era of dentistry.

Reserve Your Midas