Removable Dentures

Second-gen NanoFusion materials and a complete workflow help you deliver more smilesSchedule a Demo

Get a Free Sample

Apex dentures deliver unparalleled strength, translucency, and longevity. SprintRay 3D printing helps you deliver them in as few as 2 appointments.

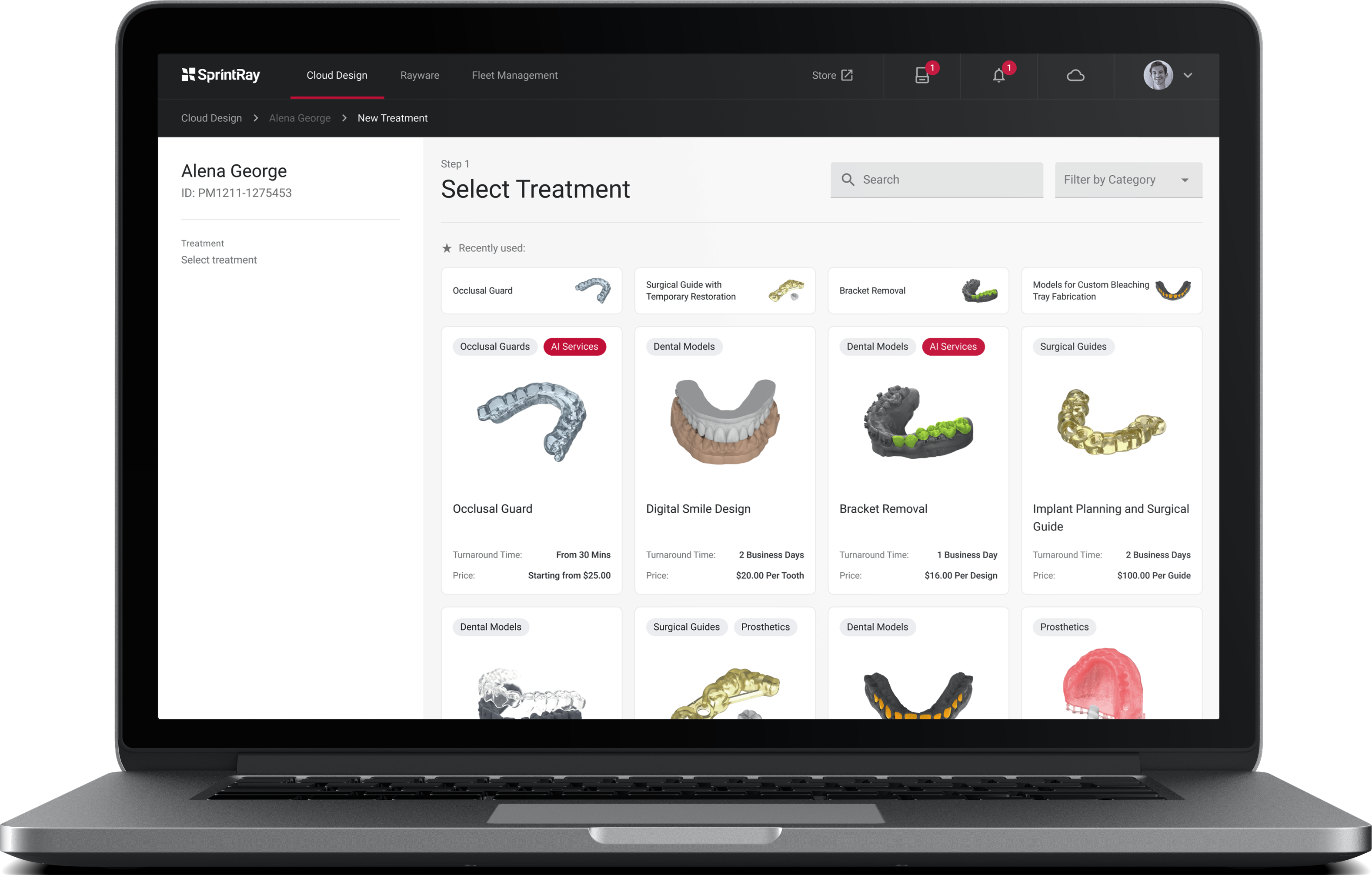

Use Cloud Design to simplify the complex treatment planning process. With SprintRay in your office, you can deliver top-quality dentures for less.

Use Cloud Design to simplify the complex treatment planning process. With SprintRay in your office, you can deliver top-quality dentures for less.

$100 Per Arch

3D printing drastically reduces the cost of custom dentures without sacrificing quality

See the Workflow

Deliver in 2 Visits

Go from initial impression to placement in 2 visits with digital records and easy reprints

Explore Design Options

Backed by Material Science

Apex materials are raising the bar for aesthetics and quality in a 3D printed denture

Explore Materials

The Simplest Denture Workflow

Scan, print, process, and deliver in as few as 2 appointments - no CAD required

Scan

Capture patient dentition with intraoral scans and/or digitized wax impressions, depending on what type of design you need.

One-click Scanner Integration

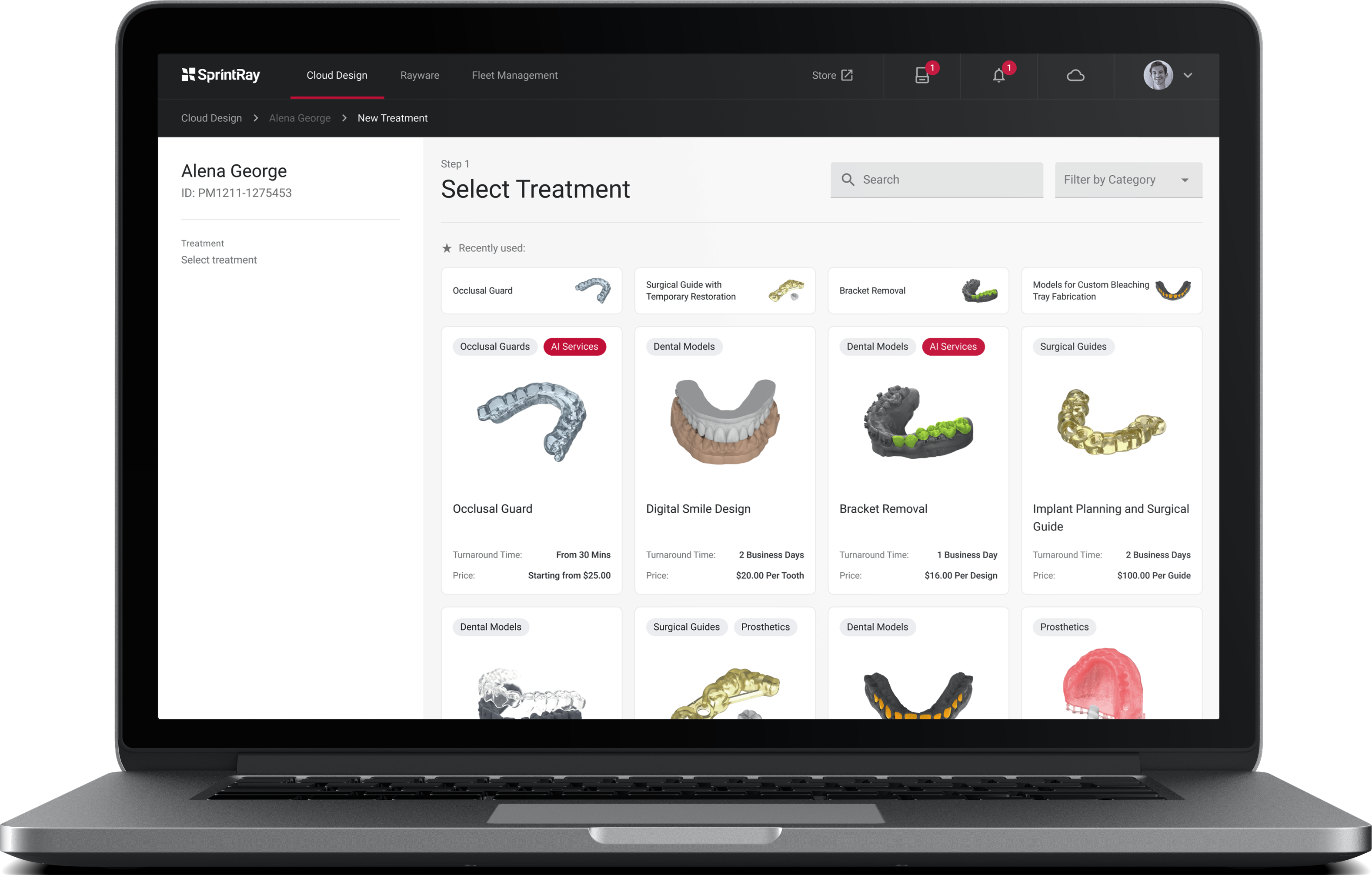

Submit a treatment

Upload scans to SprintRay Cloud Design. Choose your denture type and style for maximum customization.

Maximum Design Control

Explore Cloud Design

3D print and process

Send design files directly to your printer. Use ProWash S to clean the parts, then finish in NanoCure.

End-to-end Printing Workflow

Explore SprintRay Ecosystem

Finish and characterize

Apex materials are naturally translucent. Easily polish and characterize the denture to your desired aesthetic outcome.

Easy to Polish and Finish

Download Workflow Guide

Drew Johnson

Watch the Digital Denture Masterclass

Dr. Andrew Johnson demonstrates the digital denture workflow, from scan to deliveryIn this Masterclass, Dr. Andrew Johnson will take you through the entire workflow for 3D printing dentures, from scanning to planning to 3D printing, providing tips and tricks along the way.

Watch Masterclass

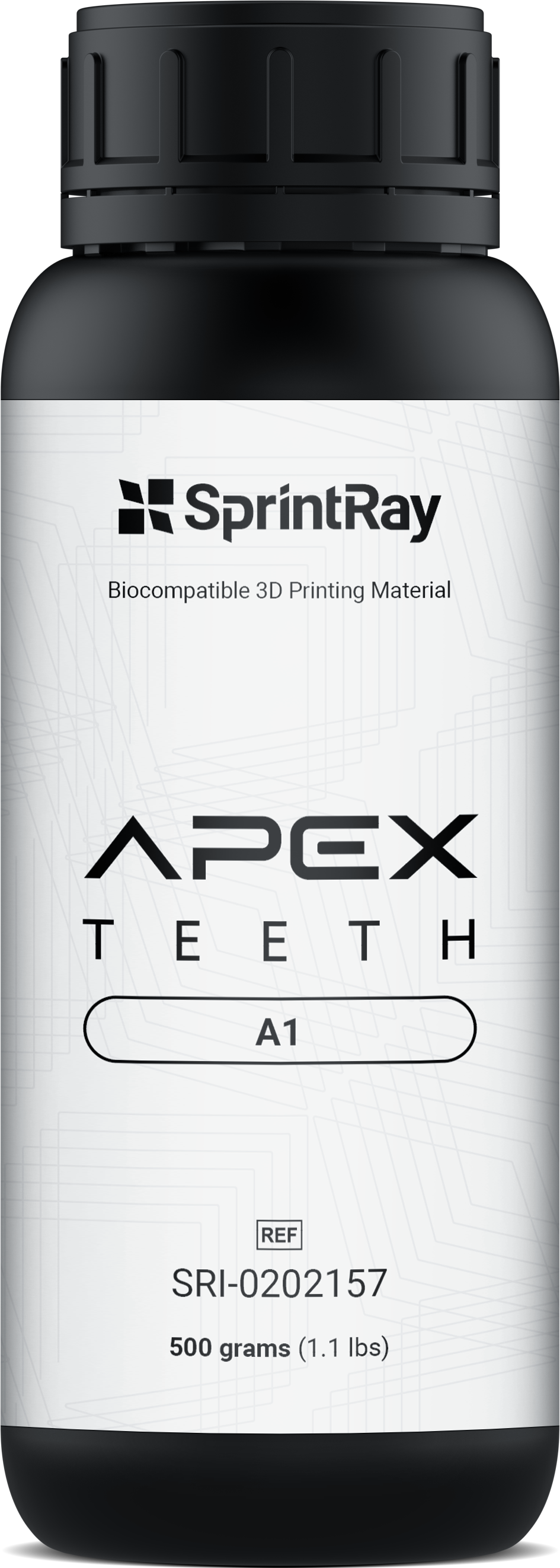

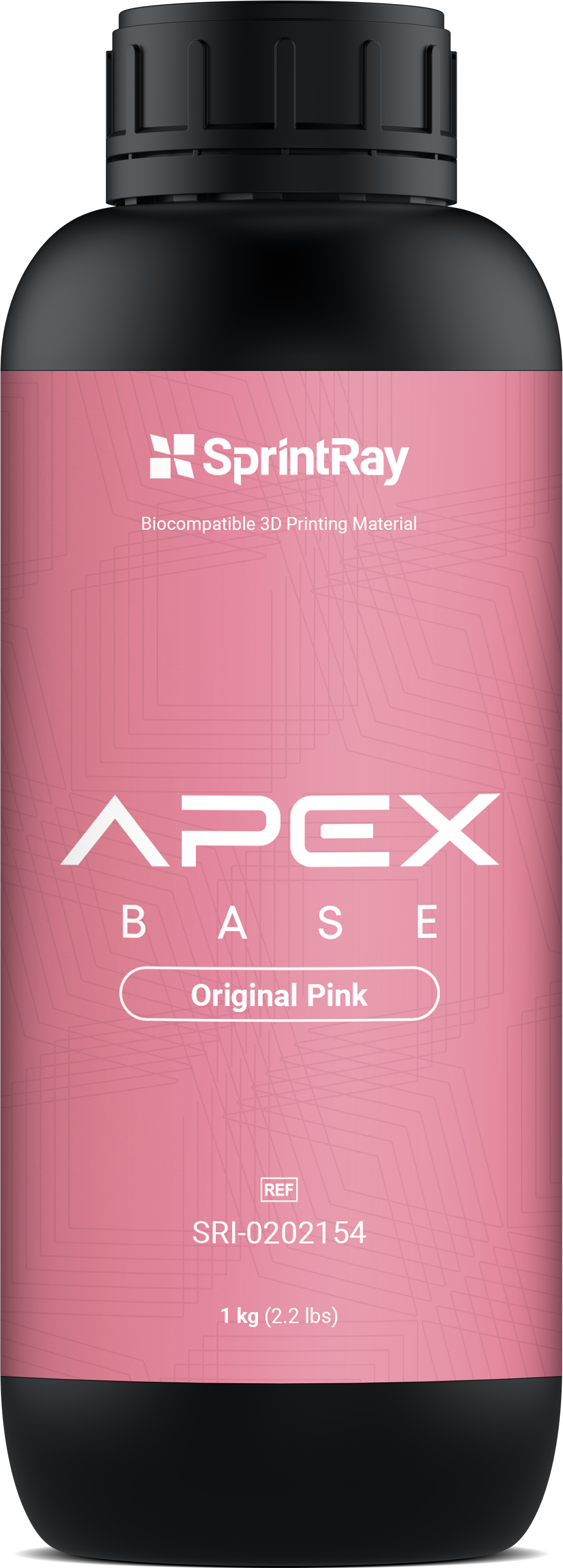

Apex Dentures - Crafted for strength, designed for beauty

Buy Now

Download Documentation

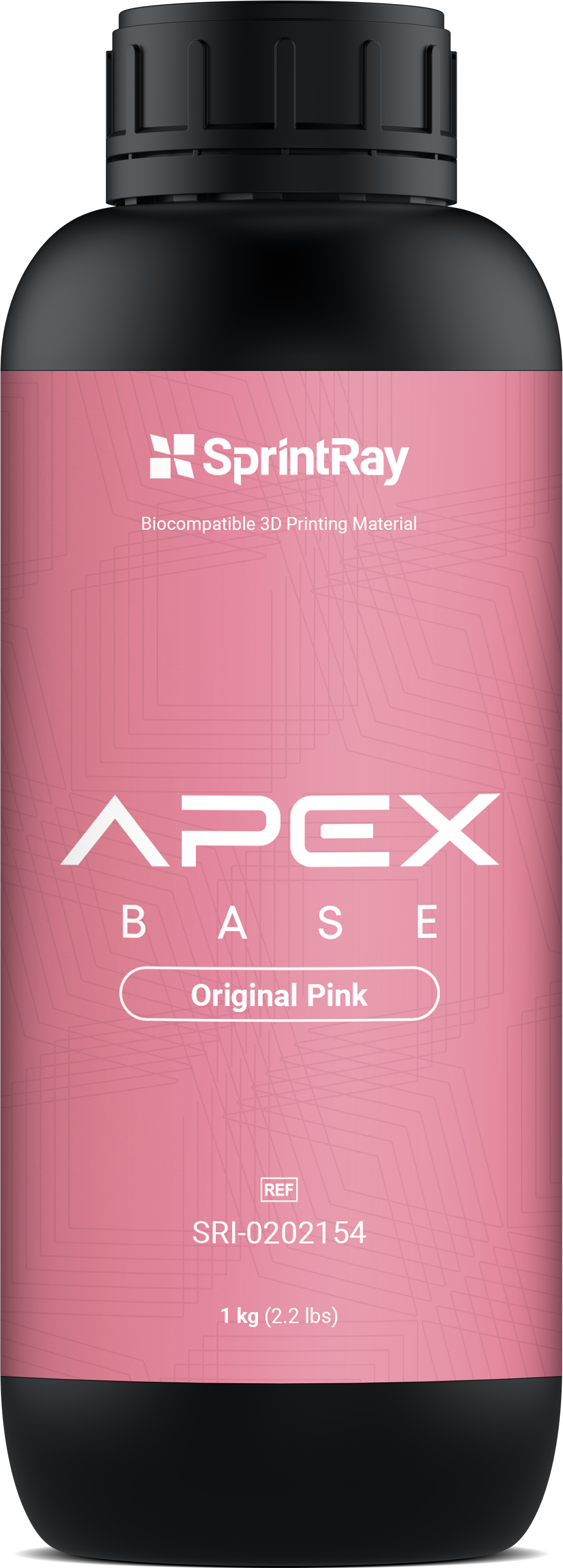

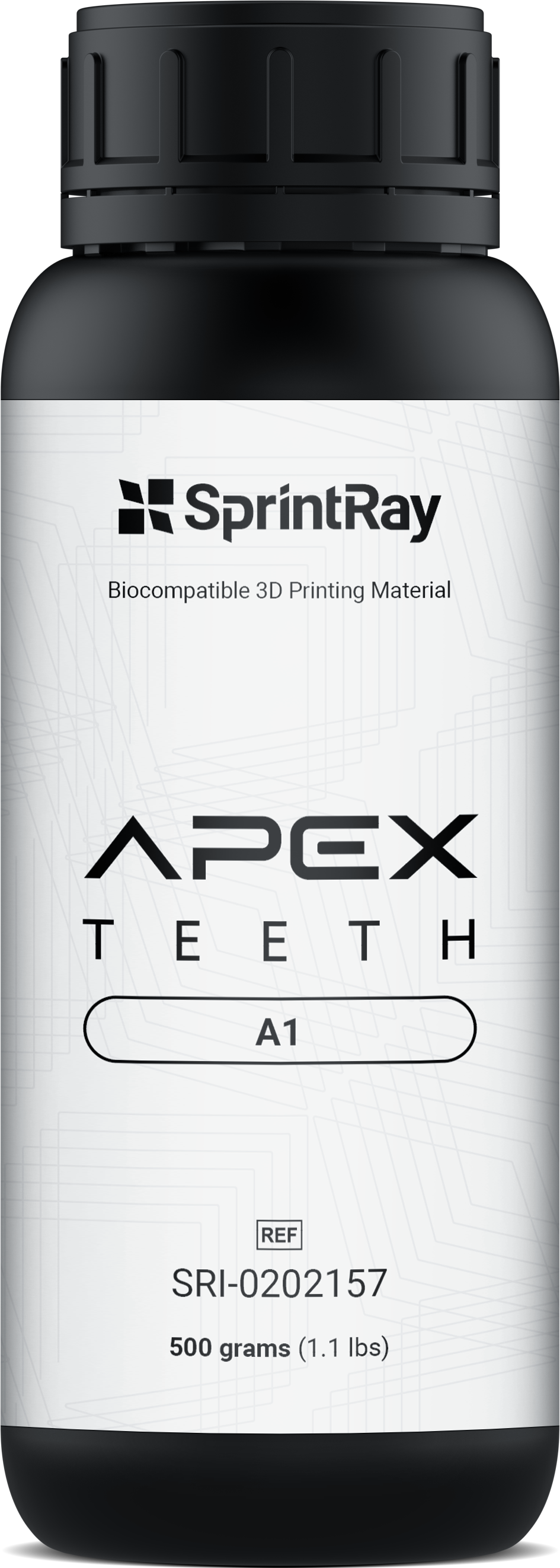

SprintRay Apex Teeth and Base represent the pinnacle of dental material science from the Biomaterial Innovation Lab. These blend NanoFusion strength with lifelike translucency for a long-lasting denture material your patients will love.

Whether you’re creating a duplicate of an existing prosthetic or starting from scratch, Apex Teeth and Base are engineered for your needs with easy post processing and characterization. The next generation of 3D printed dentures has arrived.

Whether you’re creating a duplicate of an existing prosthetic or starting from scratch, Apex Teeth and Base are engineered for your needs with easy post processing and characterization. The next generation of 3D printed dentures has arrived.

APEX ADVANTAGE

Clinically formulated for maximum translucency

NanoFusion technology for outstanding mechanicals

Available in 4 base shades, 4 tooth shades

Outstanding polishability and final aesthetics

STATS

WORK OF FRACTURE

Resistance to propagation of damageFRACTURE RESISTANCE

Maximum stress intensity before crack propagationCOFFEE STAINING

Change in color when exposed to coffee for 28 daysWEAR RATE

Volume loss during 10-year wear simulationElevating Digital Dentures

Introducing the pinnacle of dental material science from the Biomaterial Innovation Lab, setting the bar for a whole new class of 3D printed dentures.Download Workflow Guide

SprintRay Cloud Design

Appliance Design, Simplified

SprintRay Cloud Design makes it easy to turn your scans into ready-to-print 3D files. Just upload your scan files let us handle the rest.

Start Designing

DESIGN OPTIONS

Basic

Standard

Pro

Denture Design Specialists

Let our expert designers handle the CAD. We'll provide a custom appliance to match the needs of your patient perfectly.

72 hr turnaround

Submit scan data and instructions, then let our designers create a custom denture.

Tailored care

Our design team can handle any request - from simple replacements to immediate temps.

Bespoke service

Communicate with your designer and revise the treatment until everything is just right.

3 Types of Denture

Our design team can help you meet your patient where they are on their denture journey, from brand-new prosthetics to copies of existing dentures. Choose from the following design types:

New Denture

For edentulous patients who don’t have a denture today, work with our design team to deliver a whole new smile.

Copy Denture

For recreating a broken or worn-down denture. Scan the denture, then we create a replica with separated teeth and base.

Immediate Temp

A temporary denture for use immediately after teeth extraction. No patient has to leave your office without a smile.

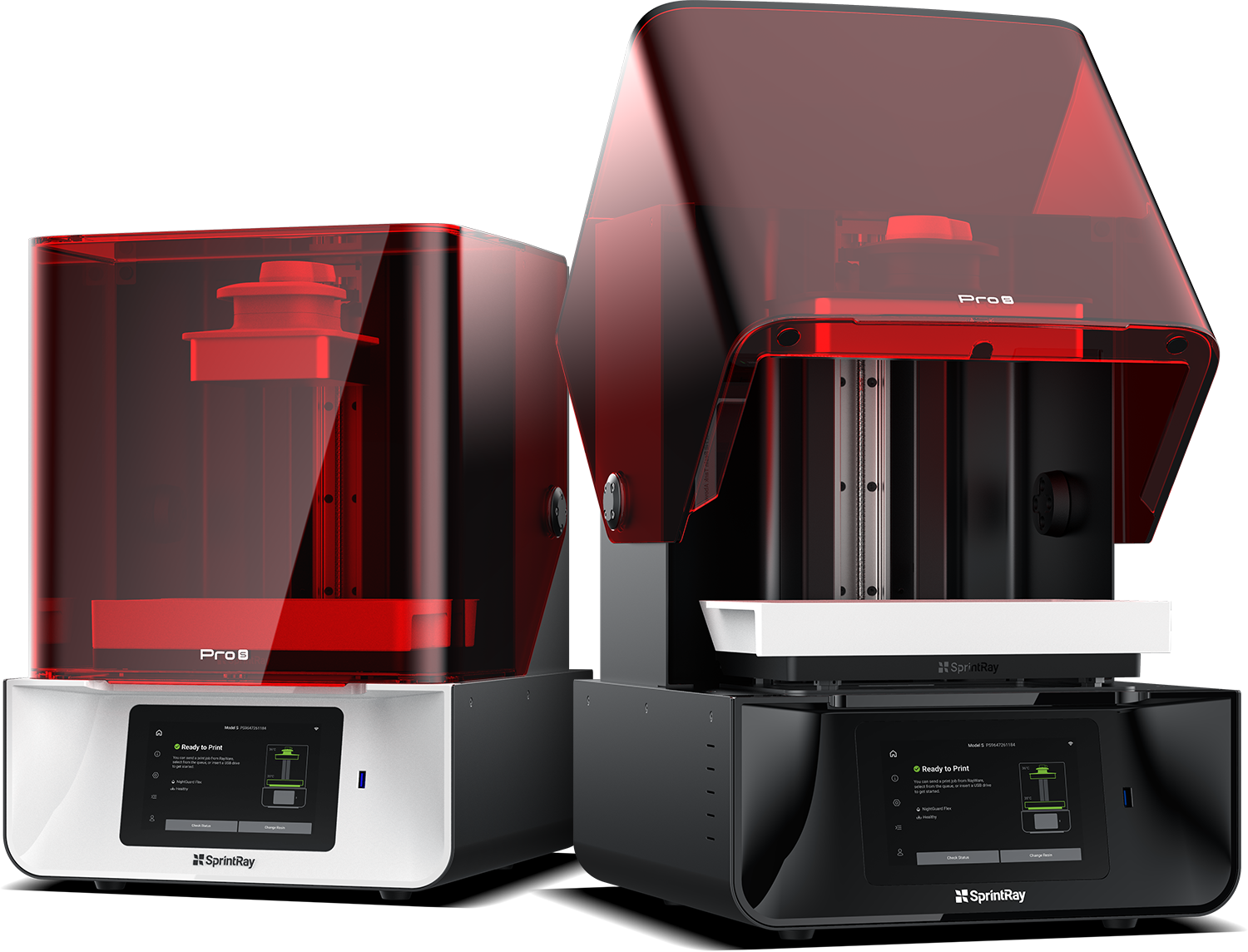

Print Confidently with SprintRay

Validated at every step from resin formulation to post curingSprintRay products are carefully designed and engineered to work together, creating simple workflows that anyone in your office can easily learn. From print job handoff to clear on-screen instructions, our goal is to help you deliver superior care while simplifying your workflow.

Schedule a Demo

Materials

The SprintRay Biomaterial Innovation Lab exists on the cutting edge of dentistry and 3D printing. Our materials are biocompatible, long lasting, and lead the industry in mechanical properties.

Explore Materials

Cutting-edge 3D printing technology put SprintRay on the map, and we continue to push the boundaries of speed and materials. Print most appliances in under an hour with incredible accuracy.

Explore Pro S

Wash

Our washing systems are designed to deliver two cleaning stages for maximum resin removal. Once the parts are clean, we run a dedicated drying fan to pull in clean air and remove IPA from the surface.

Explore ProWash S

Post Cure

The unsung hero of the 3D printing workflow, our curing devices use high-intensity light and heat to finalize all polymerization and create parts that are as strong as they are aesthetic.

Explore NanoCure