The Next Big Thing in Digital Dentistry

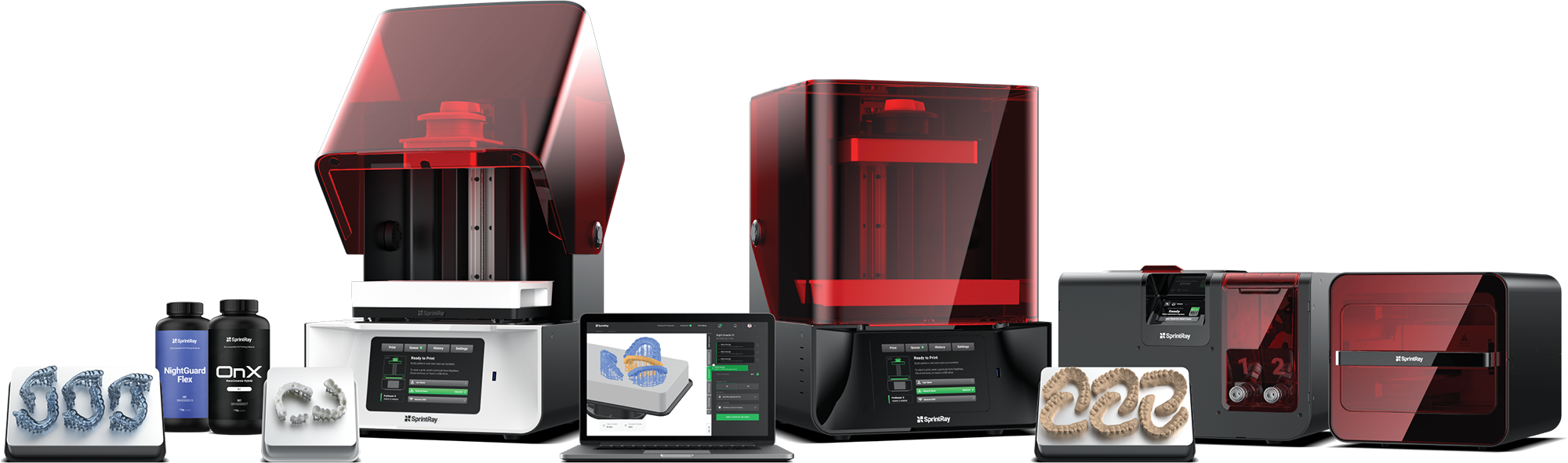

In-office dental 3D printing helps improve the efficiency of forward-thinking practices all over the world. By leveraging existing technologies that exist in digital dentistry, 3D printing enables better responsiveness to patient needs, significantly reduces manufacturing times, and opens up new treatment options. With low operating costs, minimal maintenance, and user-friendly design, SprintRay products make it easy to bring digital dentistry and 3D printing together in your practice.

Digital Dentistry and 3D Printing

Broadly speaking, digital dentistry is understood as a set of technologies for digitally capturing and manipulating patient impressions. It also involves a state of mind, a curiosity for and willingness to invest time and money in new methods. For those who don’t mind upsetting the status quo, digital dentistry provides workflow flexibility, exciting new technologies, and a superior patient experience.

The 21st Century Digital Dentist

Existing Digital Technology

- Intraoral/ bench top scanner

- Dental CAD software

- Cone beam scanner (optional)

- In-office milling machine (optional)

3D Printing

- SprintRay Pro 3D printer

- SprintRay Pro Cure Post-processing

- RayWare Pro CAD software

- Dedicated support for when things don’t go to plan

Dental 3D Printing, Explained

Our most complete 3D printing resource to date.Digital Dentistry and the 3D Printing Workflow

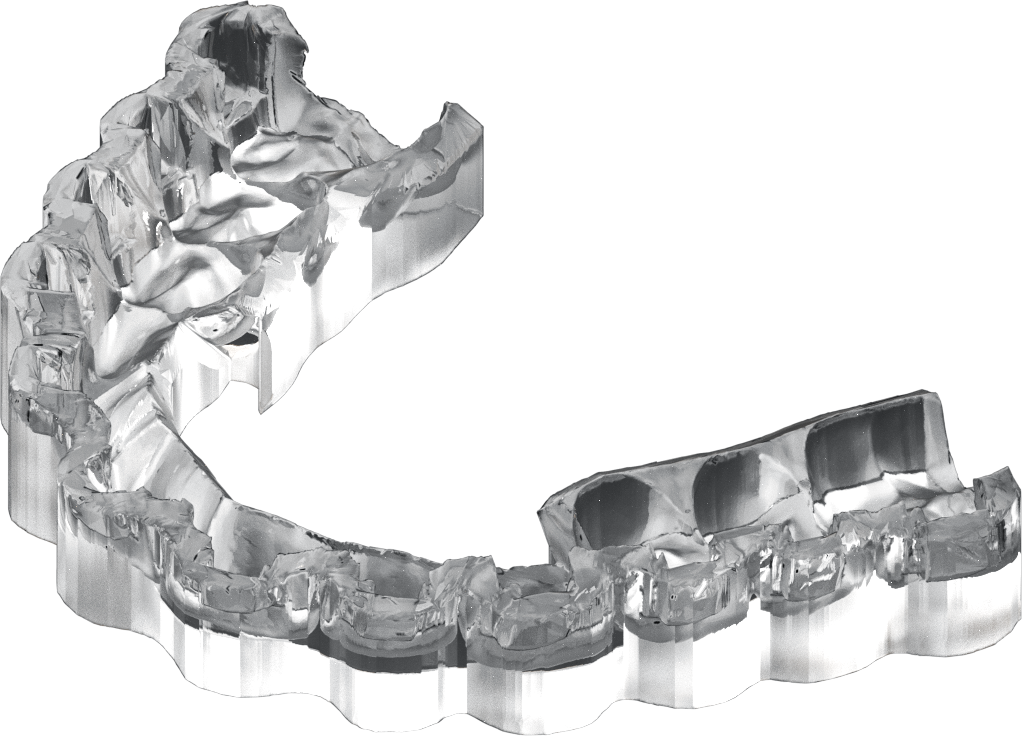

Implementing 3D printing into the dental practice has never been easier. Digital dentistry technologies such as intraoral scanners and dental CAD software easily integrate with SprintRay products thanks to the universally-accepted .STL file format for 3D models. Once you’ve left the messy impression trays and stone dental models behind, you’ll wonder how you ever lived without in-office 3D printing.

In-office Treatment Design

Partner Treatment Design

Return on Investment with 3D Printing

3D printing can help you lower costs, reduce lead times, and improve treatment outcomes. Use the calculator below to determine your ROI based on some of the most common applications.- Profit & Cost with SprintRay

- Annual Profit with 3D Printing$77,225.50

- Monthly Profit with 3D Printing$6,435.46

- Cost Per 3D Printed Appliance$30

- Monthly Equipment Cost*$583

*Cost based on total equipment sale financed for 24 months at 0% APR.

0

By Taking advantage of SprintRay 3D printing, you could net in your first year!

Profit & Cost with SprintRay

Up to

By taking advantage of Sprint Ray, if you produce the 0

selected parts over a year, you would net 0 more than if you chose to outsource your production!0

By outsourcing production, producing of appliances per year would cost you [annual lab cost]. 3D printing those parts with SprintRay would only cost you !

Cost Per Part

lowerWith your outsourced production, producing 0

parts over a year would cost you 0. Manufacturing them with Sprint Ray would only cost you 0!3D Printing Vs Outsourcing

0

With SprintRay 3D printing, you could save your patients [time savings] of wait time between appointments in your first year.

Reduced Delivery Time

Ready to Use

0 fasterWith your outsourced production, producing 0

parts over a year would cost you 0. Manufacturing them with Sprint Ray would only take you 0!| Outsourced Lab | Sprint Ray | Time Saved | |

|---|---|---|---|

| Calculated using baseline data | |||

| Production Time | $95.71 | $1,500.00 | $1,500.00 |