Placing dentures with traditional methods can take weeks, sometimes even months. With the SprintRay denture workflow, clinics can provide digital dentures in 2 patient visits. SprintRay engineered the ceramic-infused High Impact base and teeth resins for strength, durability, and longevity. Dental professionals can be confident in shortening denture production times, while patients can be confident that these prosthetics will last.

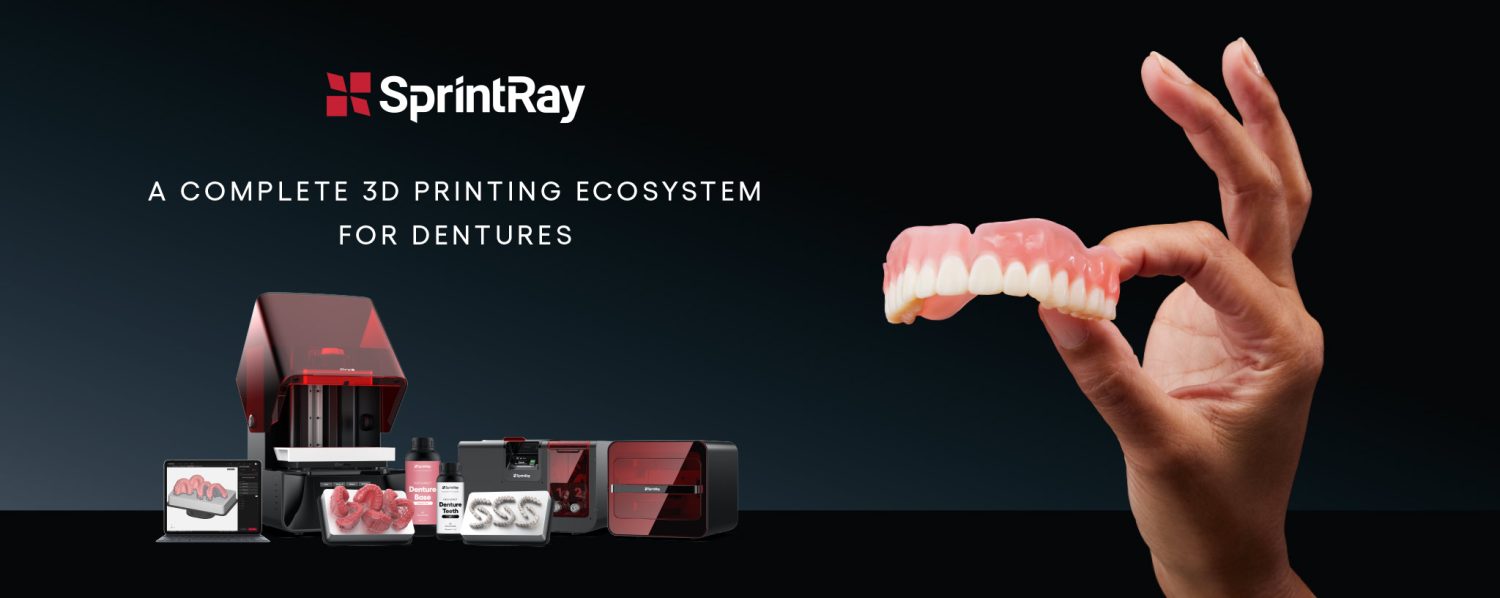

The SprintRay removable denture workflow equips dental professionals with all the tools – hardware, software, materials, and continued partnership through SprintRay training and continuing education courses – for strong and fast in-office 3D printed dentures. Experience the complete workflow for high performance, removable dentures.

- High Impact Denture Base and High Impact Denture Teeth with NanoFusion™ technology changes the landscape for 3D printing denture materials, providing a ceramic-infused resin for strong, long-lasting, and high performance 3D printed dentures.

- We designed the removable denture workflow to help dental professionals deliver digital dentures in just 2 patient visits.

- New simplified treatment planning through SprintRay Cloud Design eliminates the need for complex CAD software, starting at just $75/arch.

With SprintRay, denture production not only becomes a viable source of revenue but a simple process that benefits patients and professionals by decreasing wait times and increasing case acceptance.

High Impact Denture Base and Teeth: Unmatched Strength, Speed, and Durability

Dentures printed using High Impact Denture Teeth outperform competitor 3D printing and milled materials in durability and impact resistance, providing superior day-to-day wear over time.

Not only are these 3D printed dentures strong, they are chemically superior. Formulated with proprietary NanoFusion™ technology, the same technology used in OnX Tough, SprintRay High Impact Teeth and Base are nanoceramic, biocompatible resins for removable denture bases and teeth. NanoFusion™ technology achieves the optimal amount of ceramic in these revolutionary 3D printing materials for high impact mechanical properties. We’ve engineered these materials to last.

The Power of Cloud Design: Simplified Treatment Planning

SprintRay Cloud Design eliminates the need for complex in-office CAD. With SprintRay Cloud Design, digital denture designs keep treatment plans quick, easy, and personal.

3 new denture tiers starting at $75/arch empower doctors to meet every patient exactly where they are financially and aesthetically. SprintRay Cloud Design offers 4 denture options to match the needs of every patient.

New- For edentulous patients who don’t already have a denture. With a digitized wax rim impression, we’ll start with a try-in to get the fit right before moving on to the definitive, 2-piece High Impact denture.

Immediate – For patients who present with teeth that need to be extracted, we’ll prepare an immediate temporary appliance for use after their teeth are removed. No patient has to leave your office without teeth.

Copy – For the patients who love their denture but it has broken or is excessively worn down. Scan the denture, and we’ll make a replica, then separate the teeth and base so you can easily print an exact copy.

Reference – For patients with a denture that doesn’t fit quite right. Scan the denture, and we’ll make minor adjustments to fit and aesthetics at your direction.

Streamline your denture production with the complete, in-office 3D printing ecosystem from SprintRay. Schedule a demo to experience the ecosystem for high performance, removable dentures.