Pro Wash/Dry

Multistage automated washing system

designed for dental 3D printing

Multistage automated washing system

designed for dental 3D printing

SprintRay Pro Wash/Dry is the first fully-automated, two-stage wash and dry system built to deliver the speed, cleanliness, and ease-of-use demanded by the modern 3D printing dental clinic.

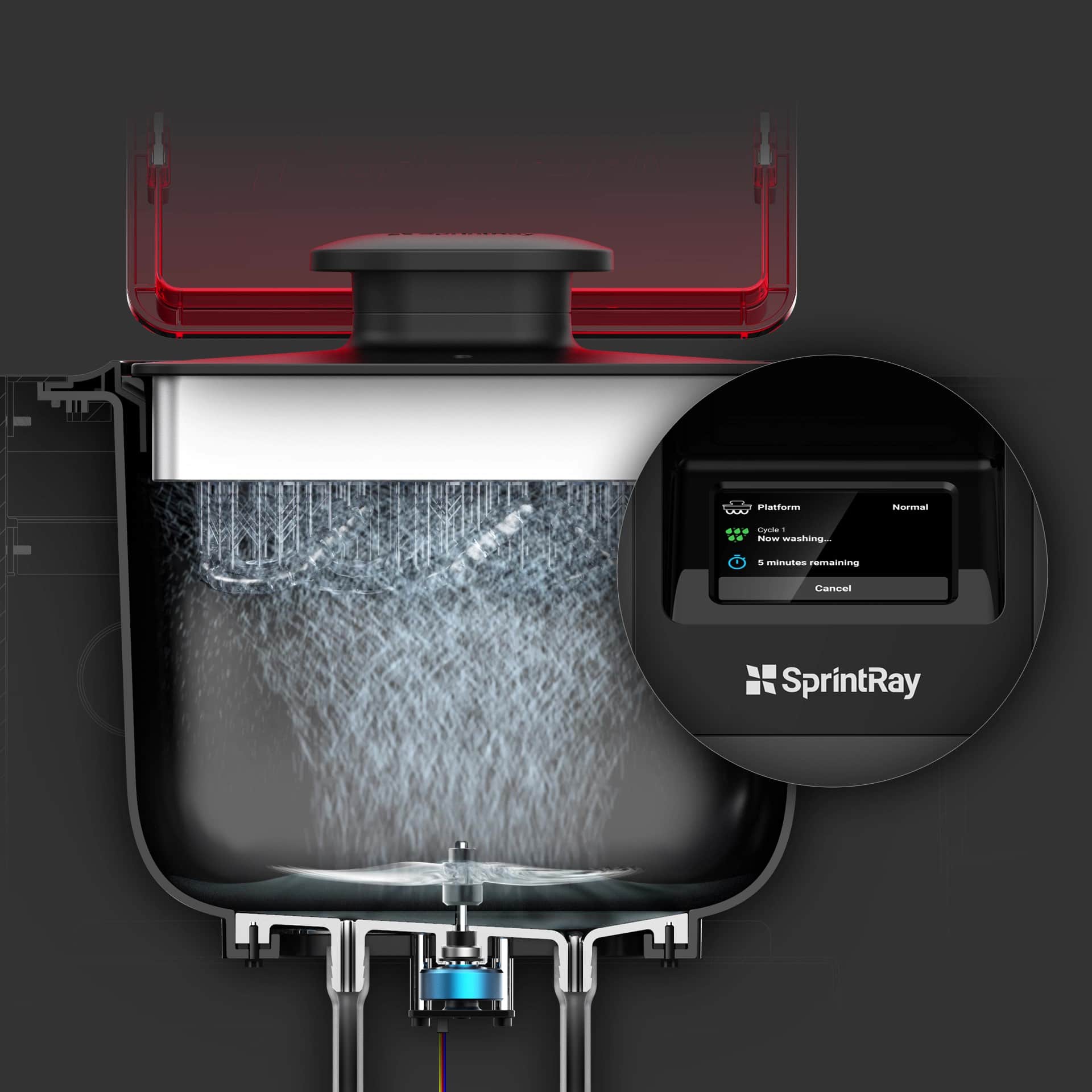

Pro Wash/Dry uses the patented Mechanical Jetting technology to rapidly wash your print parts. This unique method provides excellent cleaning power while reducing wash duration at the same time

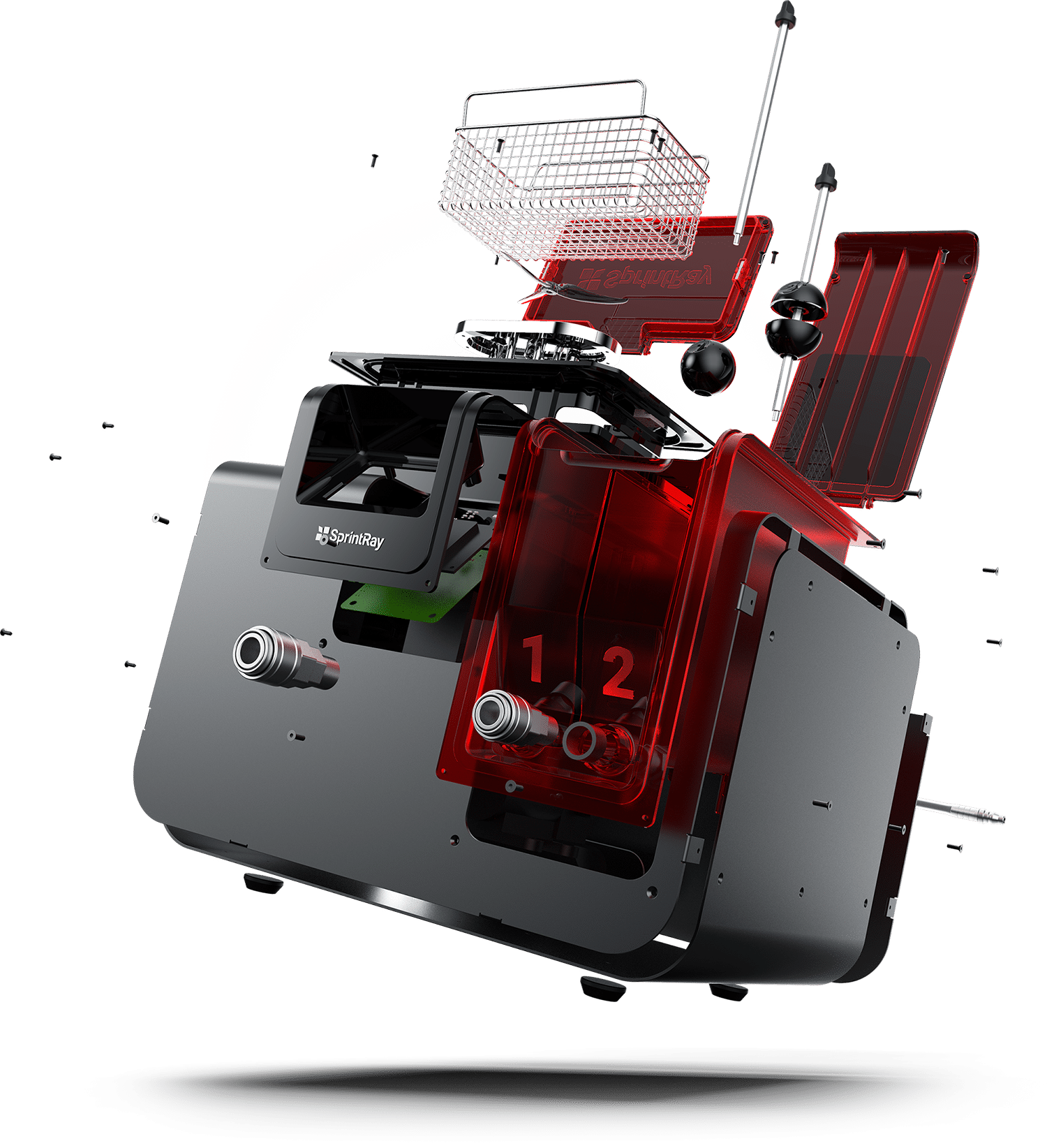

Thanks to a suite of automatic features, the only time you have to touch IPA is when you pour it into the reservoirs. Automatic pumps recycle alcohol, and quick-connect hoses whisk it away.

Pro Wash/Dry was designed with input from the dental community. Inspired by users all over the world, we leveraged the latest technology (and invented some of our own) to deliver a superior washing experience.

PATENTED

You’ve never washed parts like this before. Thanks to its high-powered motor, precisely manufactured propeller, and innovative alcohol delivery method, Pro Wash/Dry can complete a full two-stage wash and dry in less than ten minutes.

10 Minutes Wash/Dry

Submerging your parts in IPA can get your parts clean, but it results in a lot of waste alcohol. Pro Wash/Dry uses a patented method to clean without full submersion. The result: cleaner parts, less waste, and faster workflows.

Pro Wash/Dry was built to be used with SprintRay Pro. Once your print job is finished, simply place your platform in the cradle and press ‘Start’. Pro Wash/Dry will automatically perform a two-stage wash and then dry your parts.

Science Removes the Guesswork

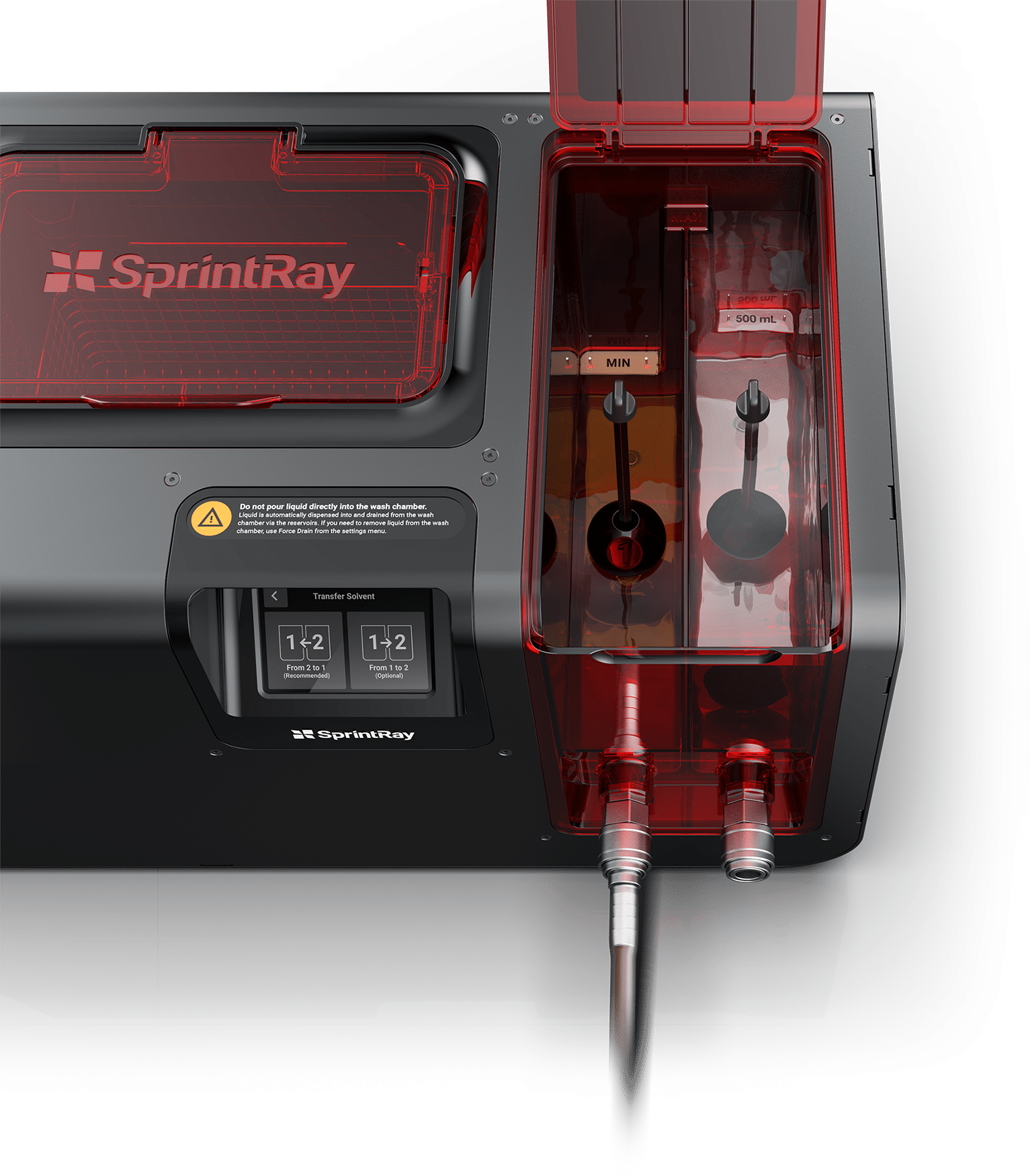

Pro Wash/Dry comes with precalibrated hydrometers that sink in clean IPA and float when it’s dirty. Since you always know when it’s time to refresh your IPA, your parts will always come out clean.

Pre-calibrated

Pro Wash/Dry can operate with a little as a half-liter of alcohol thanks to the unique way it uses IPA to clean your parts. It’s a small victory for your pocketbook, a big win for the environment, and a quantum leap in 3D printing wash efficiency.

500mL to Start

Advanced electronics and mesh-wire plumbing connect all the chambers in Pro Wash/Dry. Recycle dirty alcohol from one chamber to the other with the press of a button. No mess required in your practice.

Reduced Waste

To drain IPA from Pro Wash/Dry, we’ve provided a quick-connect hose. It snaps into place, creating a water-tight seal instantly. When you’re finished draining, simply press the release ring to instantly stop the flow.

Clean IPA Removal

We know that one of the most precious resources in a dental clinic is time. So in addition to making Pro Wash/Dry run an extremely fast cycle, we made it dead simple to operate. If your staff can operate a smartphone, they can use Pro Wash/Dry with very little training. And to reduce maintenance, we sourced innovative materials that are resistant to chemicals.

Made with an aluminum chassis and chemical-resistant, translucent plastic, Pro Wash/Dry requires almost no maintenance.

To prevent chemicals from dripping onto the touchscreen computer, we set the electronics back under a small shroud. One less thing to worry about.

Made with an aluminum chassis and chemical-resistant, translucent plastic, Pro Wash/Dry requires almost no maintenance.

To prevent chemicals from dripping onto the touchscreen computer, we set the electronics back under a small shroud. One less thing to worry about.

Made with an aluminum chassis and chemical-resistant, translucent plastic, Pro Wash/Dry requires almost no maintenance.

To prevent chemicals from dripping onto the touchscreen computer, we set the electronics back under a small shroud. One less thing to worry about.

Platform Wash Envelope

17 x 12.7 x 7.6 cm

7 x 5 x 3 in

Basket Wash Envelope

17 x 12.7 x 12.7 cm

7 x 5 x 5 in

Liquid Level Monitoring System

Conductive Sensor

Liquid Saturation Monitoring System

2 Pre-calibrated Hydrometers

Wash Liquid Compatibility

Isopropyl alcohol 91% (Recommended)

Isopropyl alcohol 99%

Ethanol

Disposal Method

2 Standard Quick Connect Drain Ports

1 Quick Connect Drain Hose with Automatic Cut-off

Wash Liquid Capacity

2 liters per reservoir

Minimum Wash Solution Required

500 mL Per Reservoir

User Controls

3.5″ color touch-screen

Pre-defined Wash/Dry preset

System Controls

Microcontroller with upgradable firmware via USB

Safety Sensors

Automatic Start/Stop Sensors

Platform vs Basket Detection

Fill Level Sensor

Power Requirement

100–240v (Via DC Adapter)

Dimensions

30 x 30 x 46 cm

12 x 12 x 18 in

Packaging Dimensions

36 x 36 x 50 cm

14 x 14 x 20 in

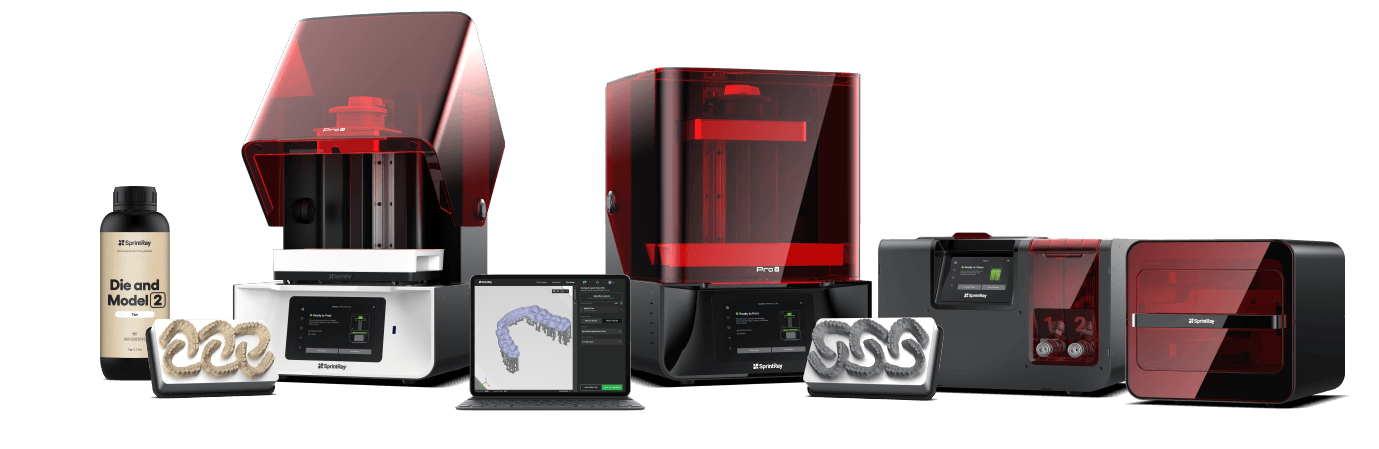

The SprintRay 3D printing ecosystem is designed for the unique needs of dental professionals. With SprintRay as your partner, pushing the boundaries of what’s possible in dentistry has never been easier.