The 30-Minute Dental 3D Printer

Here’s why DLP is right for digital dentistry.

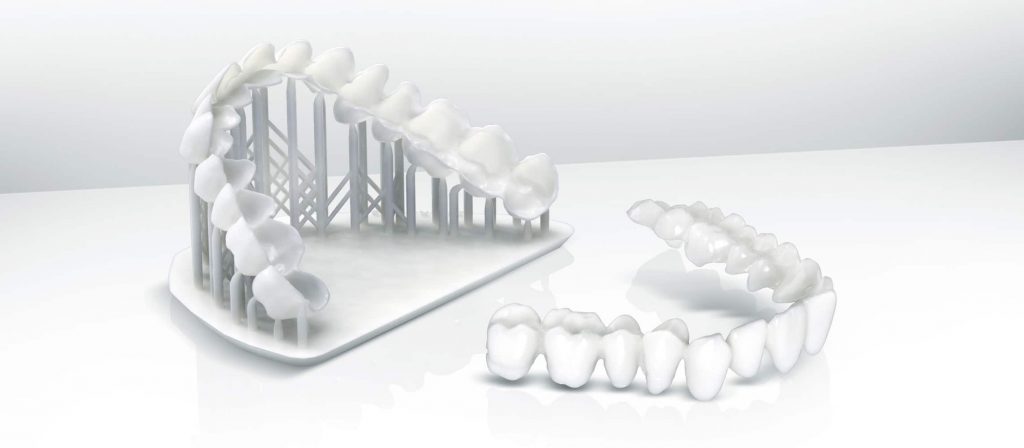

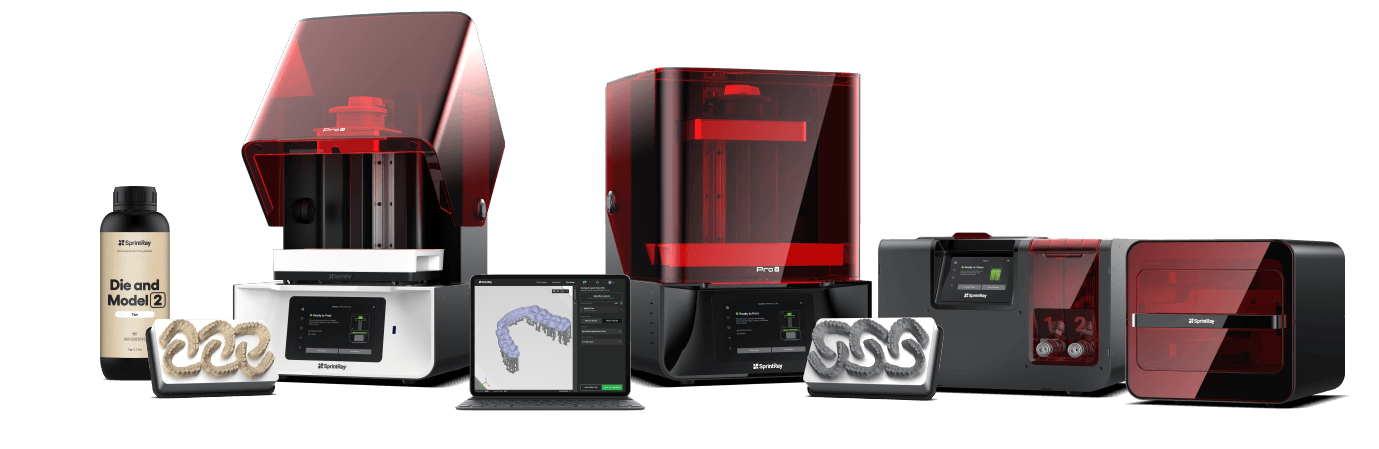

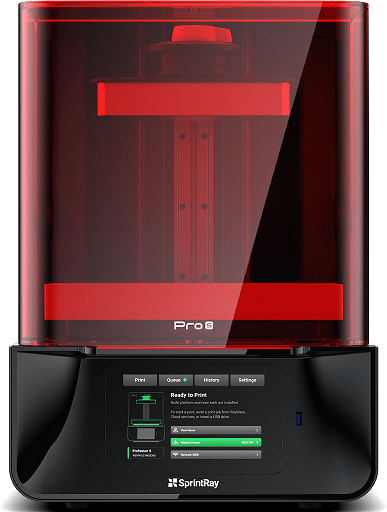

While the ability to produce dental appliances in-office is revolutionary to digital dentistry, the speed of an individual 3D printer can make a substantial difference. A practical way to measure the outcome of this speed is to measure its output via the 30-minute test, which shows both the on-demand printing speed as well as the overall throughput of the printer. Because of its bespoke DLP projector, SprintRay Pro can produce a full platform of dental arches in around 25 minutes.

Dental 3D printers reached an inflection point when biocompatible materials became widely available for desktop machines. These FDA-compliant materials made 3D printed parts safe for intraoral use and offered great mechanical properties, propelling desktop 3D printers into dental practices all over the world.

Dental 3D printers reached an inflection point when biocompatible materials became widely available for desktop machines. These FDA-compliant materials made 3D printed parts safe for intraoral use and offered great mechanical properties, propelling desktop 3D printers into dental practices all over the world.