Longevity Study:

3D Printed Night Guards

NightGuard Flex outperform traditionally fabricated night guards

in strength and wear tests

Open Access Journal of Dental Sciences

Tufts University School of Dental Medicine, USA

A new clinical study has confirmed what many dental practitioners already knew: the SprintRay ecosystem enables the in-office fabrication of night guards of superior quality.

3D printed occlusal guards have quickly become a favorite with practitioners and patients. The combination of easy design, fast delivery, and low cost have allowed clinicians to protect more smiles with innovative resins like NightGuard Flex.

Researchers discovered statistically significant differences in

wear between the 3D printed and traditionally fabricated

guards. NightGuard Flex and Firm showed higher resistance to

wear than the Biocryl splint.

Scientific Wear Study

In a recent study, researchers at the Tufts University School of Engineering compared the wear of 3D printed night guards to that of traditional, lab manufactured night guards.

SprintRay Night Guard Flex, SprintRay Night Guard Firm, and Clear Splint Biocryl 2mm (NGP) were tested against each other for wear resistance as part of the study. Researchers fabricated guards using NightGuard Flex and Firm using a SprintRay Pro55 3D printer, while the NGP splints were made using a standard pressure molding machine.

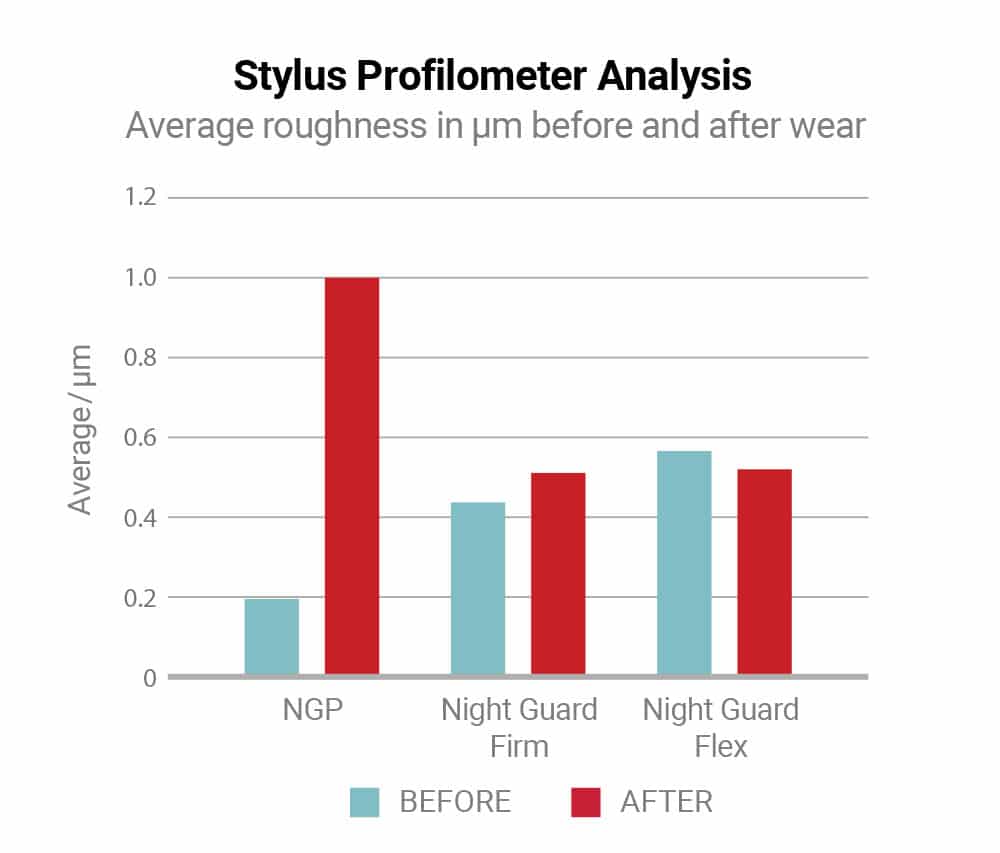

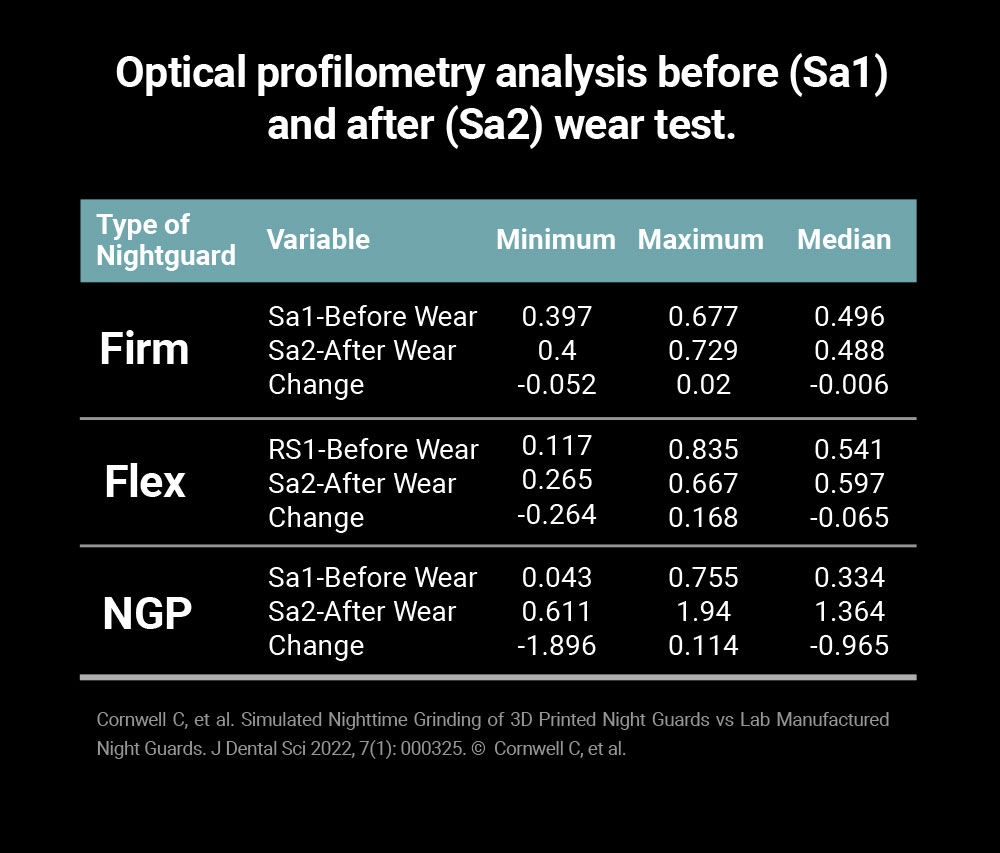

The scientists used a wear simulator to check for wear resistance. The samples were run through 20,000 wear cycles, under a load of 25 N to mimic a month of normal night time grinding. Enamel antagonists ensured an accurate simulation of wear.

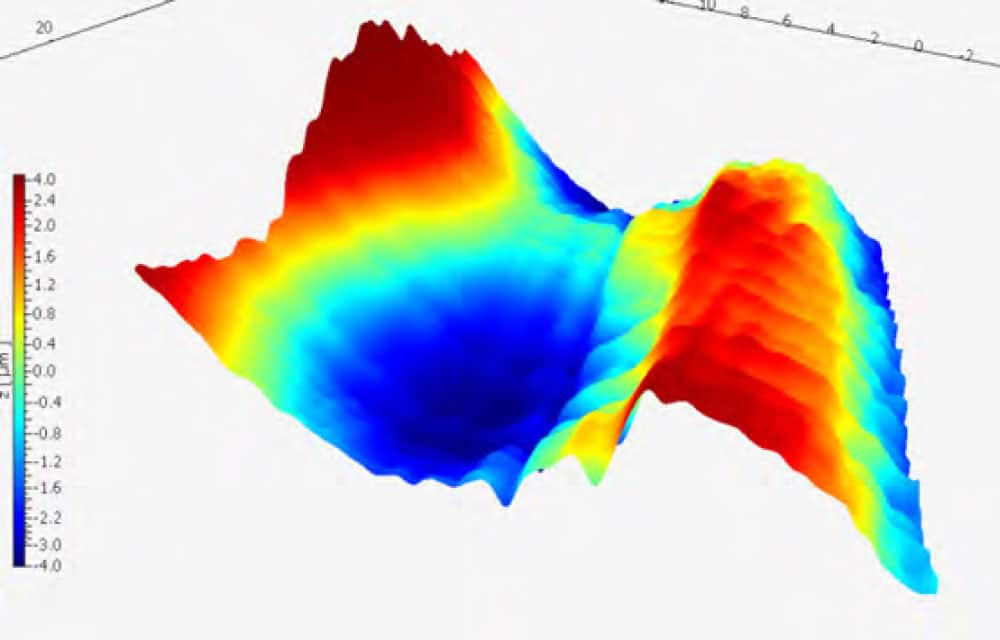

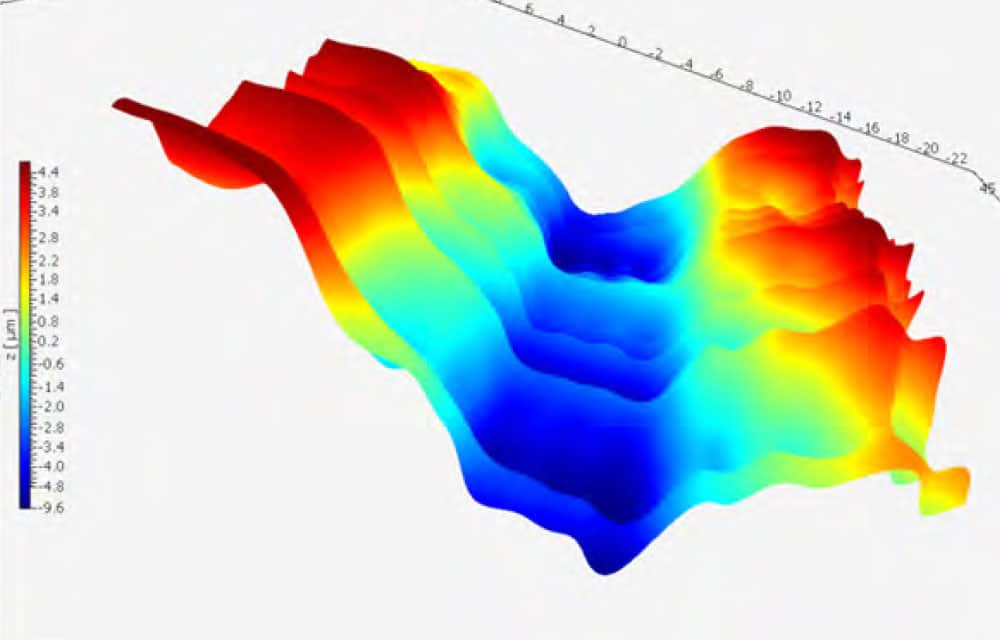

Using stylus and laser 3D profilometry, researchers discovered a statistically significant differences in wear between the 3D printed and traditionally fabricated guards. NightGuard Flex and Firm showed higher resistance to wear than the Biocryl splint

Engineered Material Perfection

There is no place for compromise in a dental workflow. At SprintRay, we believe that printing materials are as crucial to 3D printing as the hardware and software. In line with this view, we have made substantial investments toward research and development of 3D printing material, namely the game-changing SprintRay Night Guard Flex and SprintRay Night Guard Firm resins.

Our hardware, software, and materials work in perfect harmony. We aim to deliver efficiency, quality, and control with every print job. Our 3D printing materials are meticulously engineered and have undergone rigorous testing to eliminate cytotoxicity, match the industry’s highest standards, and deliver outstanding longevity, strength, and aesthetics.

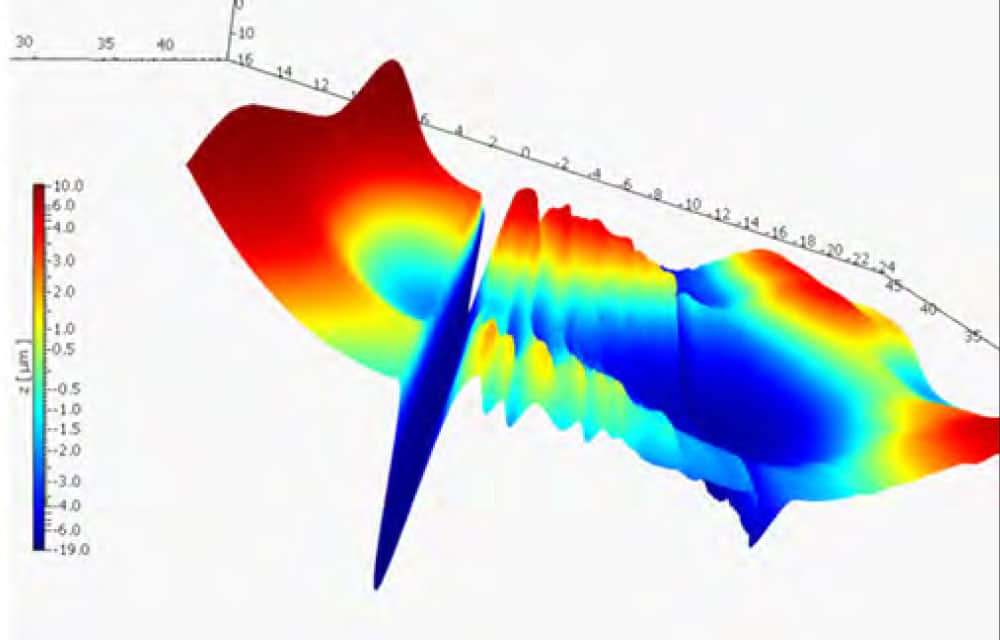

Optical profilometry image showing 3D surface topography of NGP after wear test.

Optical profilometry image showing 3D surface topography of NGP after wear test.

Optical profilometry image showing 3D surface topography of NGP after wear test.