“I could never imagined as a first year dental student that my life would take so many crazy turns and I’d end up doing what I’m doing today,” Corey Glenn said of his recent foray into creating a 3D printed prosthetic ear. But technology can take us into wild places.

Oh, The Places We’ll Go

When his cohort began treatment for a patient who had been in a major car accident, Dr. Glenn wanted to help in any way he could. As a digital dentist with experience using his SprintRay 3D printer for all manner of dental applications, he decided to try his hand at making a 3D printed prosthetic ear to replace what had been lost in the accident.

The Power of Printing

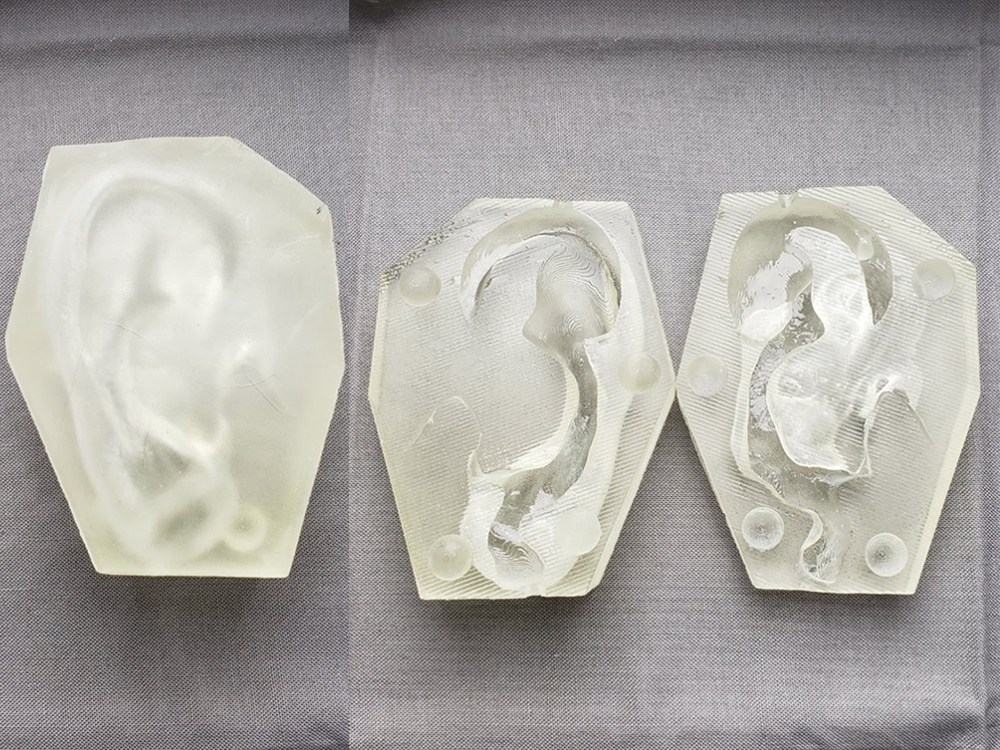

To begin with, they took a scan of the man’s opposite ear so that they had a digital model of what it might look like. Using Meshmixer, Dr. Glenn was able to flip the scan and subtract the underlying soft tissue. Instead of just printing the ear and then making a model, he decided to make an injection mold. Using NextDent IBT in his SprintRay 3D printer, he printed out the mold and injected it with PVS to prove the concept. Seeing that the mold was successful, he sent it off to an anaplastologist to inject silicone and finish the ear.

Printing in the Hands of Experts

One of the big reasons that SprintRay pivoted into dental is because we saw the awesome power of this technology to change lives. While it isn’t as flashy as aerospace, dental care touches almost every single person in some way. By empowering experts to use our products, 3D printing affects end-users directly. It’s what motivates us to manage our open certified resin system, to provide above-and-beyond customer support, and to make sure that our products are as user-friendly as possible.

Dr. Glenn created a video of sculpting the mold in Meshmixer. Interested parties can watch it here.