Introducing: SprintRay Pro Wash/Dry

At SprintRay, our mission is to offer cutting-edge technology solutions to systematically remove pain points from dental workflows. Today, we’re proud to announce SprintRay Pro Wash/Dry. This system provides a simple, automated washing experience that allows you to spend less time worrying about post processing, and more time with your patients. Featuring patented Mechanical Jetting technology, Pro Wash/Dry is the final piece of the SprintRay Frictionless Workflow.

Designed for You

When we set out to build a SprintRay wash system, we knew that it needed to be efficient and easy. For us, that meant a rapid wash cycle that required the lowest number of touches. It meant not having to fill a 2L bucket with solvent. It meant that forgetting about your models wouldn’t result in them deteriorating in a vat of solvent.

We also wanted to simplify solvent management. Knowing when to replace solvent due to resin saturation is a huge problem with existing wash systems. Once resin has saturated your solvent, we wanted to remove the dread that comes with tipping a large bucket of flammable material over a small disposal vessel. Impressed as we are by many of the DIY kits out there, we felt that dental offices shouldn’t have to cobble together home grown solutions.

We also wanted to simplify solvent management. Knowing when to replace solvent due to resin saturation is a huge problem with existing wash systems. Once resin has saturated your solvent, we wanted to remove the dread that comes with tipping a large bucket of flammable material over a small disposal vessel. Impressed as we are by many of the DIY kits out there, we felt that dental offices shouldn’t have to cobble together home grown solutions.

These criteria came out of countless conversations we’ve had with our user base over the last few years. It’s our policy that you – our innovative user base of dental professionals – knows what you need better than we do. So through office visits, surveys, conversations, and focus sessions, we believe that you’re going to love the way SprintRay Pro Wash/Dry unlocks efficiencies in your digital manufacturing workflow.

Fast, Easy, Efficient

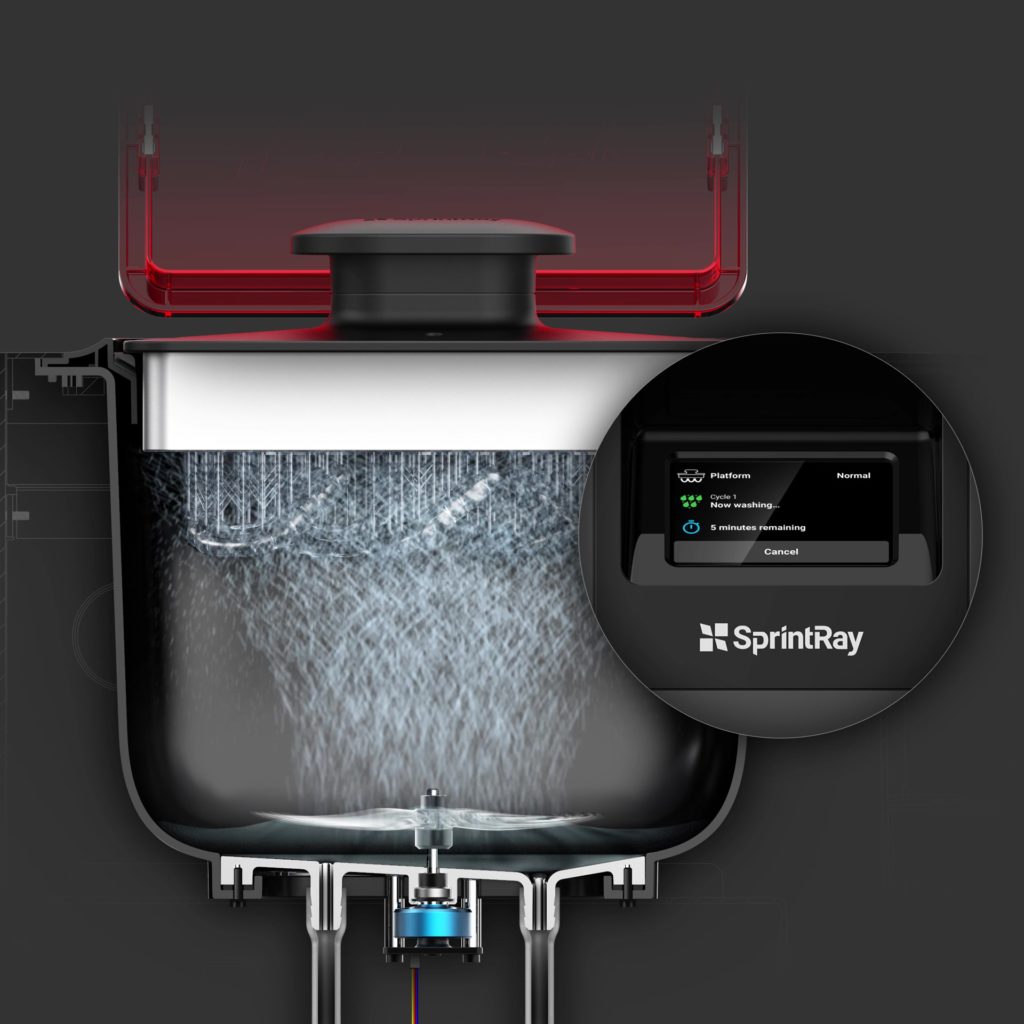

To put it succinctly: SprintRay Pro Wash/Dry automates the process of washing 3D printed parts. With our patented Mechanical Jetting technology, we’ve unlocked efficiencies that not only allow for a full two-stage wash cycle in just 10 minutes, but we’re able to do with just 500mL of alcohol per cycle. Even better, Mechanical Jetting provides a better, more thorough wash. Using a motor that spins at over 10,000 RPM and a high-tech propeller, we’re pushing automated wash systems forward into the 21st century.

When we spoke with dental professionals about washing parts, we discovered that solvent management is a huge headache for dental offices. With Pro Wash/Dry, you’ll always know when to replace solvent thanks to its pre-calibrated, bespoke hydrometers that float when your solution has become saturated. When it is time to change, use the included hose and quick-connect ports on the front of the reservoirs to whisk solvent away. Thanks to the quick-connect ports, this process is rapid and creates no mess.

It Just Works

All of this technology, design, and innovation comes together when you have a finished print that’s ready for post-processing. If you’re using Pro95, simply slide the platform into the wash basin and press ‘Start.’ As the user walks away to continue working on other things, Pro Wash/Dry automatically pumps solvent from the first reservoir into the wash chamber. Once the first-stage wash is done, this solvent is pumped out and replaced by what is in chamber 2 for a fine wash. Next, the wash chamber is emptied and the parts are blown with air to aid in the drying process.

Our mission is to make digital technology so easy that you don’t have to think about it. We believe Pro Wash/Dry achieves this goal by creating a fully automated system without compromising on efficacy. We’re so excited to share it with you.

Our mission is to make digital technology so easy that you don’t have to think about it. We believe Pro Wash/Dry achieves this goal by creating a fully automated system without compromising on efficacy. We’re so excited to share it with you.