When it comes to 3D printing, software forms the backbone of an accurate, precise and speedy printing workflow. A robust, well-designed and easy-to-use software can make the difference between a good printed part and a superb one that’s suitable for clinical use.

Our mission at SprintRay has always been to design 3D printing technology that improves the everyday experience of dental professionals. Our cutting-edge and thoughtfully designed set of software impeccably complements our hardware, working in synergy to provide solutions to dentistry’s most common digital workflow problems. The unique features in SprintRay’s family of software give both walk-away freedom and complete control of your print jobs, benefits that tend to be mutually exclusive when it comes to 3D printing.

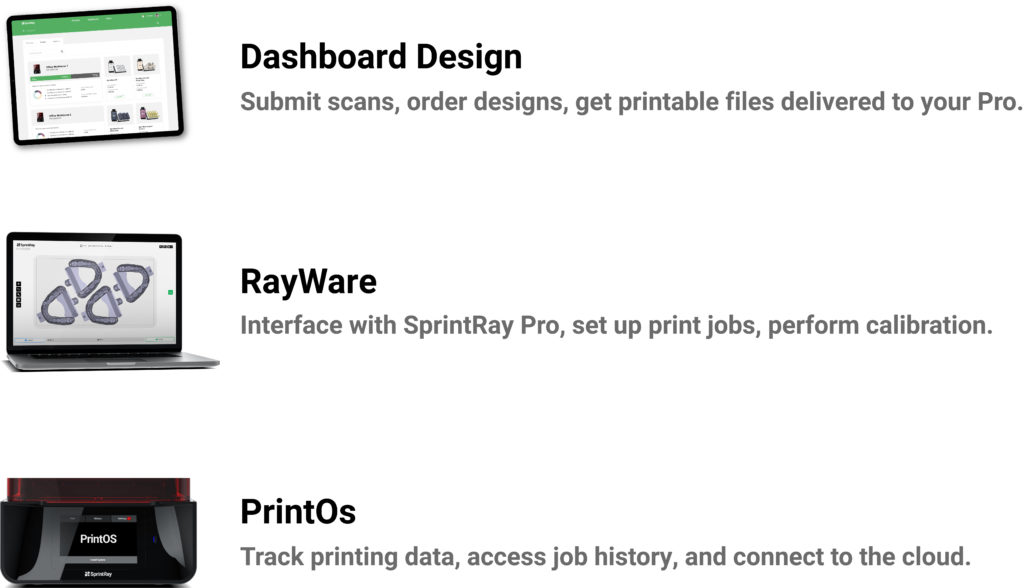

RayWare

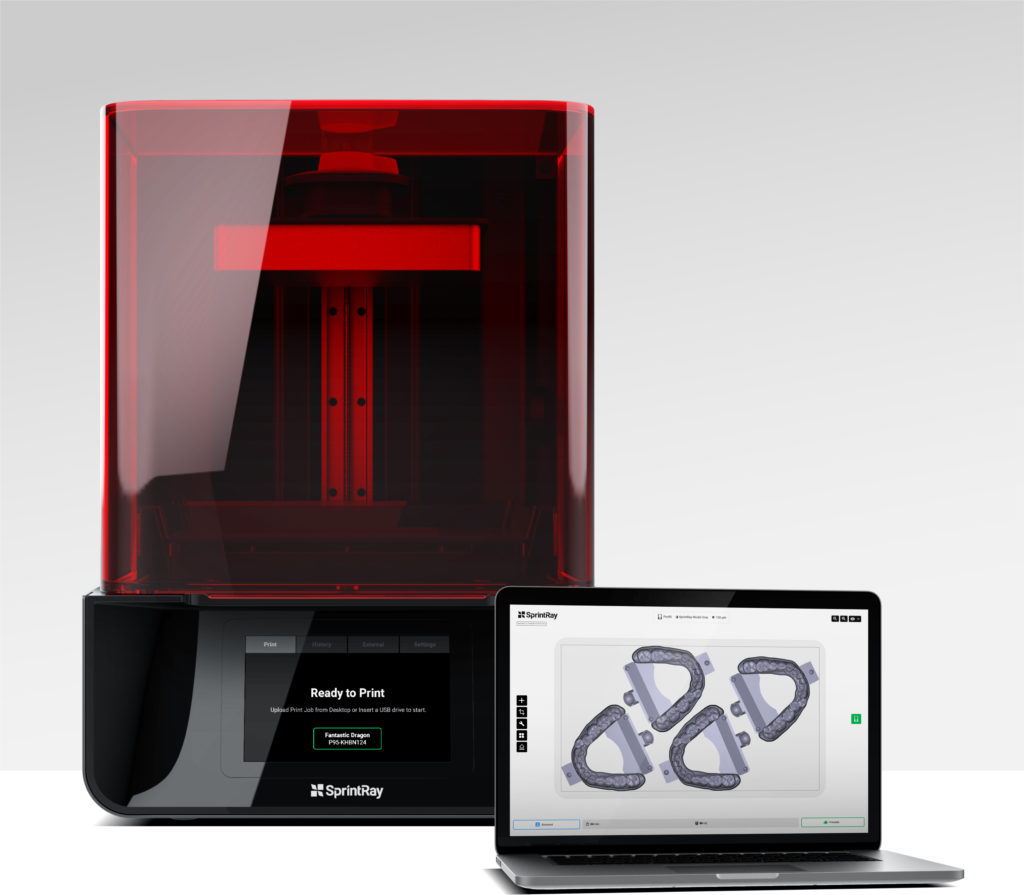

RayWare is the central hub of SprintRay’s dental 3D printing software ecosystem. In a nutshell, it is the intermediary step between receiving your designs and printing them, and it’s how you talk to your SprintRay Pro.

Designed specifically for dental professionals, RayWare functions to make the setup, management, and monitoring of your print jobs simple and efficient. Designed to deliver dental software solutions while leveraging every possible avenue to improve our products, RayWare operates in tandem with other SprintRay products and software to help unlock new pathways to practice control.

RayWare’s user-friendly interface makes it simple to use while its powerful CAD automation features help improve workflow efficiency. Using RayWare, you can put together models, fix issues, and finally nest everything together, all with a few simple clicks

RayWare presents a range of revolutionary new technology that will go a long way in elevating the dental 3D printing experience. You can find a comprehensive list of features on the SprintRay website, but some of the recent additions to our software include:

Parallel slicer – Slicing is the process of breaking a model down into a thousand separate images, often a resource-intensive process. With parallel slicing, however, this process is made incredibly efficient, enabling up to 10X faster slicing speeds.

Pixel Toning – Pixel toning uses advanced software to dynamically adjust each projector flash on a pixel-by-pixel basis, resulting in the improved surface quality of models. With a 5% accuracy increase, pixel toning can help make models with unparalleled surface quality.

Unprecedented Speed – The combined effects of parallel slicing and pixel toning result in model production speeds up to 2X faster than the baseline, an incredible boost to your workflow efficiency and a true testament to how well our software and hardware work together.

Other features of RayWare include creating custom supports, printability helper, and cloud connectivity.

Dashboard Design

Our latest design service platform, Dashboard Design is our solution to handling the design step of dental 3D printing for you. Dashboard Design is where your printing process all comes together, where you order designs before printing them on your SprintRay printer.

The design process of in-office 3D printing is often seen as a pain-point in the 3D printing workflow. Some practitioners take it upon themselves to learn dental CAD. However, this is not a viable solution for all doctors all of the time. Others circumvent handing the design step altogether by outsourcing it to an external laboratory, sacrificing full control for convenience. Recognizing the friction that these existing workflows can create, we created Dashboard Design.

Aimed at reducing the friction in your digital workflow by eliminating the need for dental 3D printing software knowledge, Dashboard Design connects your hardware and software to bring you a completely frictionless printing process. All you have to do is upload your scanned files to Dashboard Design, select your desired treatment option and leave us your instructions. We will take care of the rest.

Dashboard Design will automatically match you with one of our dental design experts to complete your appliance design. Features such as the 3D model viewer and a live chat option ensure that you are in control of and connected to your design at every step. Once done, all that is left for you to do is add your desired resin and press ‘print’.

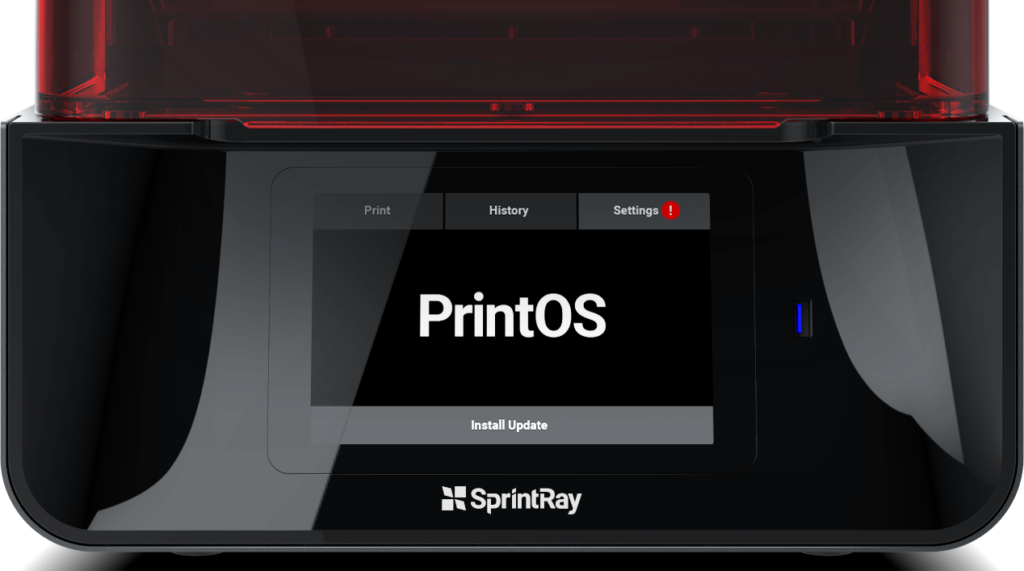

PrintOS

And last but most definitely not least, PrintOS is the operating system behind our cutting-edge 3D printing line-up. PrintOS controls the many features on our hardware, including sensors, heating systems on the printers, print queues, and printing history. It provides easy access to print settings and administration, including setup, troubleshooting, and data collection.

A smart and intuitive software, PrintOS will guide you through every step of the printing process, making the SprintRay line-up incredibly easy to navigate. It’s hard to overstate the impact that PrintOS has on the everyday business of 3D printing, because it operates on every single function of SprintRay Pro. Pixel Toning, Parallel Slicer, and improvements to speed and accuracy are all made possible by the world’s first purpose-built operating system designed to run the functions of SprintRay Pro.

The Right Dental 3D Printing Software for the Job

While often overlooked, software is at the center of the 3D printing process. It can help elevate the quality of the end product as well as facilitate the ease and accuracy with which you can print.

Our tightly integrated and seamless SprintRay ecosystem reduces the complexities of the 3D printing process. Our family of software works together to bring about rapid, accurate, beautiful results without the steep learning curve that often comes with CAD/CAM systems.

When combined, SprintRay’s software and hardware work in synergy to elevate your 3D printing experience. Their perfect fusion enables a completely automated workflow, minimizing the need for user interaction and required time.